OzFDM PA6 (Nylon) Deep Dive

A Deep Dive into OzFDM PA6 Nylon Filament

Here at Oz FDM, we're passionate about providing our customers with the best possible materials for their 3D printing endeavors. Today, we're taking a closer look at our PA6 Nylon filament, a robust and versatile material ideal for a range of demanding projects.

Printing Parameters for Success:

To achieve optimal results with OzFDM PA6 Nylon, here are the recommended printing settings for your reference:

- Extruder Temperature: 260°C (This is higher than the typical printing temperature for PLA or ABS, so ensure your extruder can handle it.)

- Bed Plate Temperature: 100°C (A heated bed is crucial to prevent warping.)

- Fan Speeds: 0% (Using a cooling fan can lead to warping and cracking. Keep the Fan Speeds as low as possible. A fully enclosed printing environment is recommended.)

- Enclosure Required: Full enclosure (A fully enclosed chamber helps maintain a consistent temperature throughout the print, minimizing warping.)

- Chamber Temperature: 55-65°C (Set your exhaust fan to maintain this temperature range within the enclosure.)

- Flow Ratio: 1.0 (Our testing revealed a flow ratio of 1.0 to be optimal for accurate filament extrusion.)

- Warp Reduction: Utilize a brim during printing to combat warping, especially for larger prints.

Tested and Optimized:

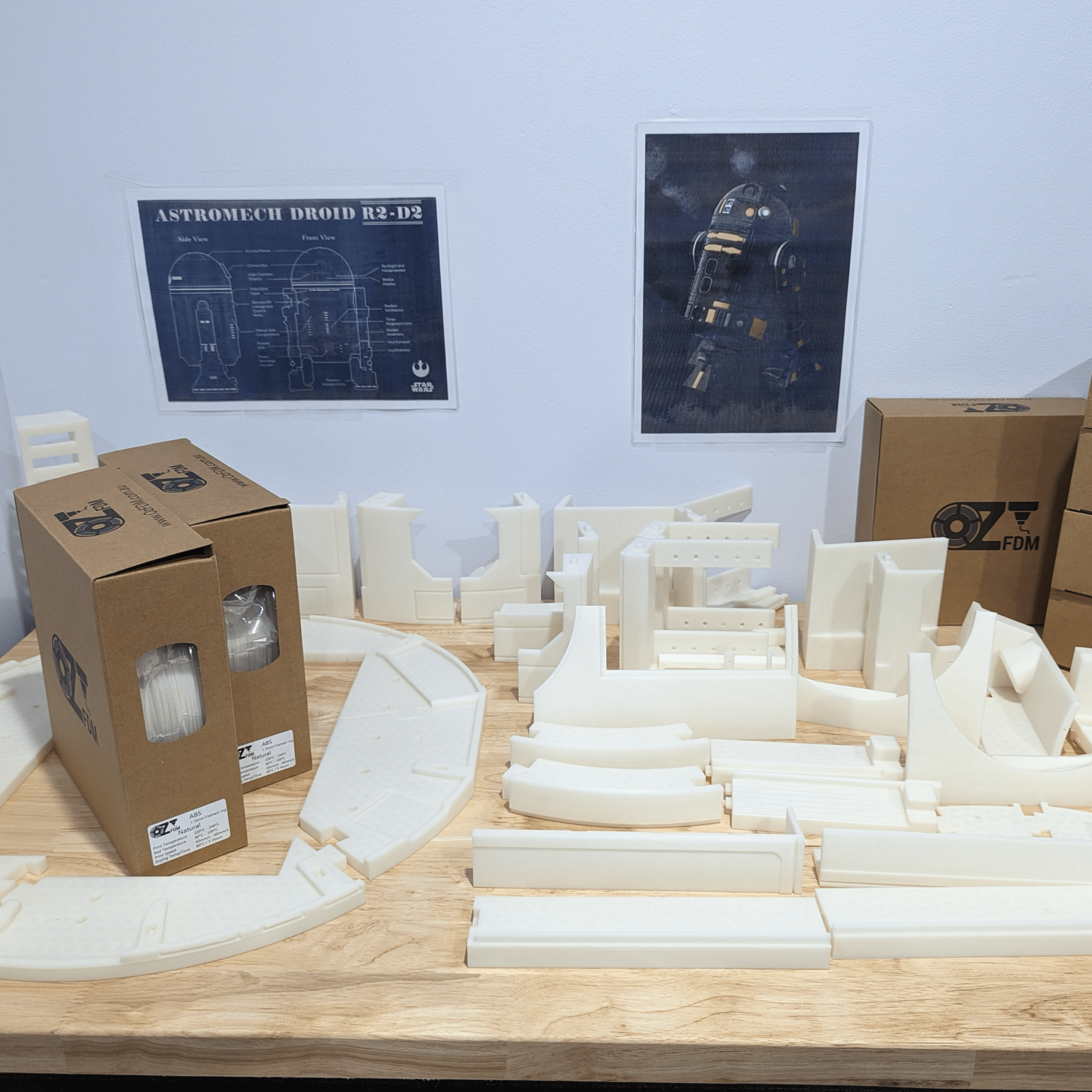

These settings were established through rigorous testing on our Bambu Lab X1C 3D printer. We achieved successful prints at a speed of 80mm/s with a 0.4mm nozzle and a layer height of 0.2mm. However, it's important to note that these settings may need slight adjustments depending on your specific printer model and setup. We recommend starting with these as a baseline and fine-tuning from there.

The Power of Nylon:

PA6 Nylon offers a unique combination of properties that make it ideal for various applications, including:

- High Strength and Durability: Nylon boasts exceptional mechanical strength and wear resistance, making it perfect for functional parts and prototypes that need to withstand significant stress.

- Heat Resistance: Compared to PLA or ABS, PA6 Nylon exhibits superior heat resistance, allowing it to perform well in environments with elevated temperatures.

- Dimensional Stability: With proper printing techniques, PA6 Nylon prints can maintain their shape well, making them suitable for parts requiring dimensional accuracy.

Mould Making Made Easy:

One of the most exciting applications of PA6 Nylon is its use in mould making for resin casting. Its smooth surface finish and high heat resistance make it ideal for creating robust and reusable moulds for casting intricate resin parts.

Nylon vs. ABS and PETG:

While PA6 Nylon shares some similarities with popular filaments like ABS and PETG, there are key distinctions:

- Strength: Nylon generally surpasses ABS and PETG in terms of overall strength and wear resistance.

- Heat Resistance: Similar to ABS, Nylon offers superior heat resistance compared to PETG.

- Warping: Nylon is more prone to warping than ABS or PETG. However, with proper printing techniques and a fully enclosed printing environment, warping can be effectively minimized.

Moisture Control is Key:

Important Note: PA6 Nylon is hygroscopic, meaning it readily absorbs moisture from the environment. This can lead to printing issues like decreased strength and surface imperfections. To ensure optimal performance, it's crucial to dry your PA6 Nylon filament at the recommended temperature before printing. We recommend 80°C for 8-12 Hours and up to 24 Hours if printing errors still occur.

The Final Print:

OzFDM PA6 Nylon filament is a powerful tool for experienced makers seeking to push the boundaries of their 3D printing projects. By following the recommended printing parameters and utilizing a fully enclosed printing environment, you can achieve exceptional results with this high-performance material.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.