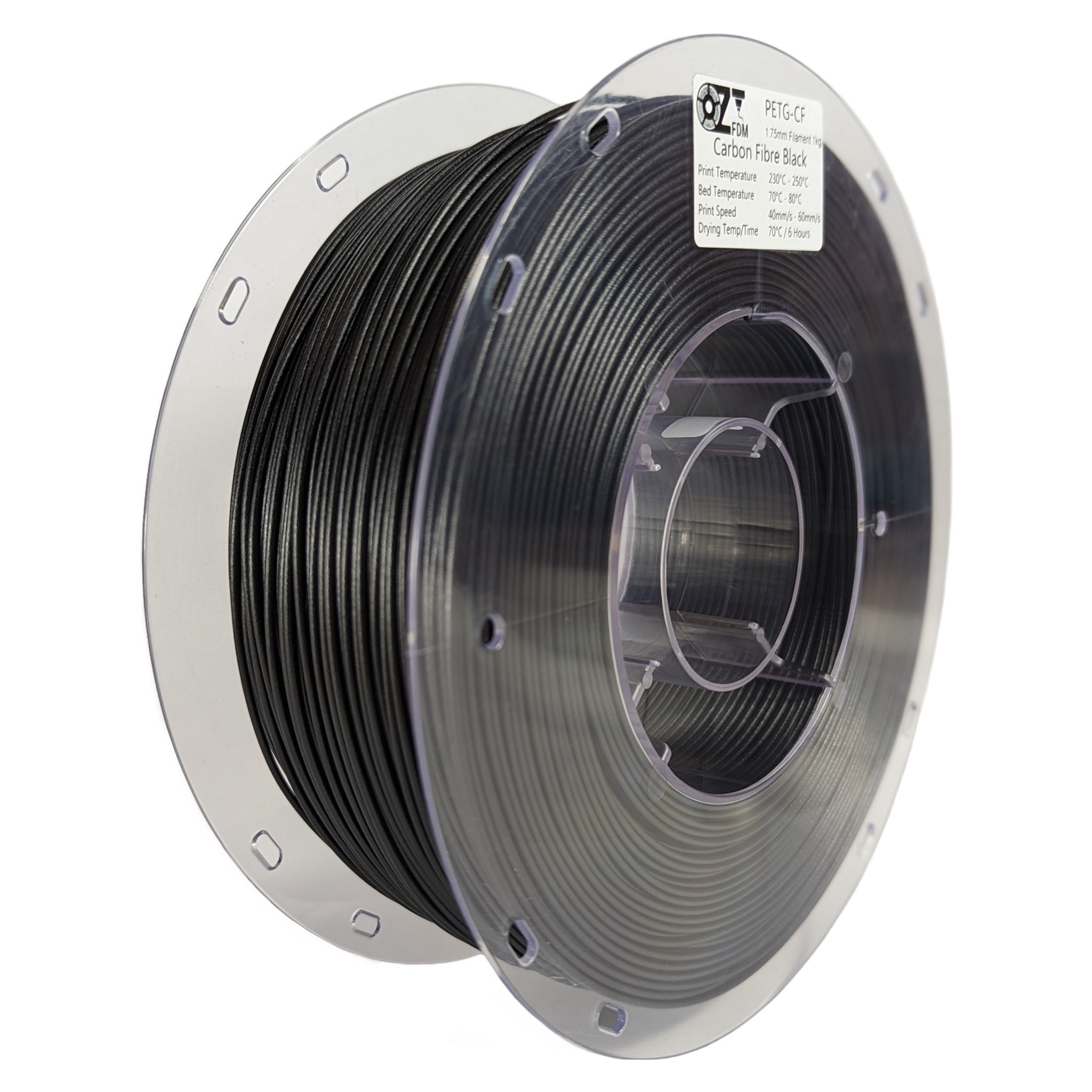

1.75 mm PETG-CF Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

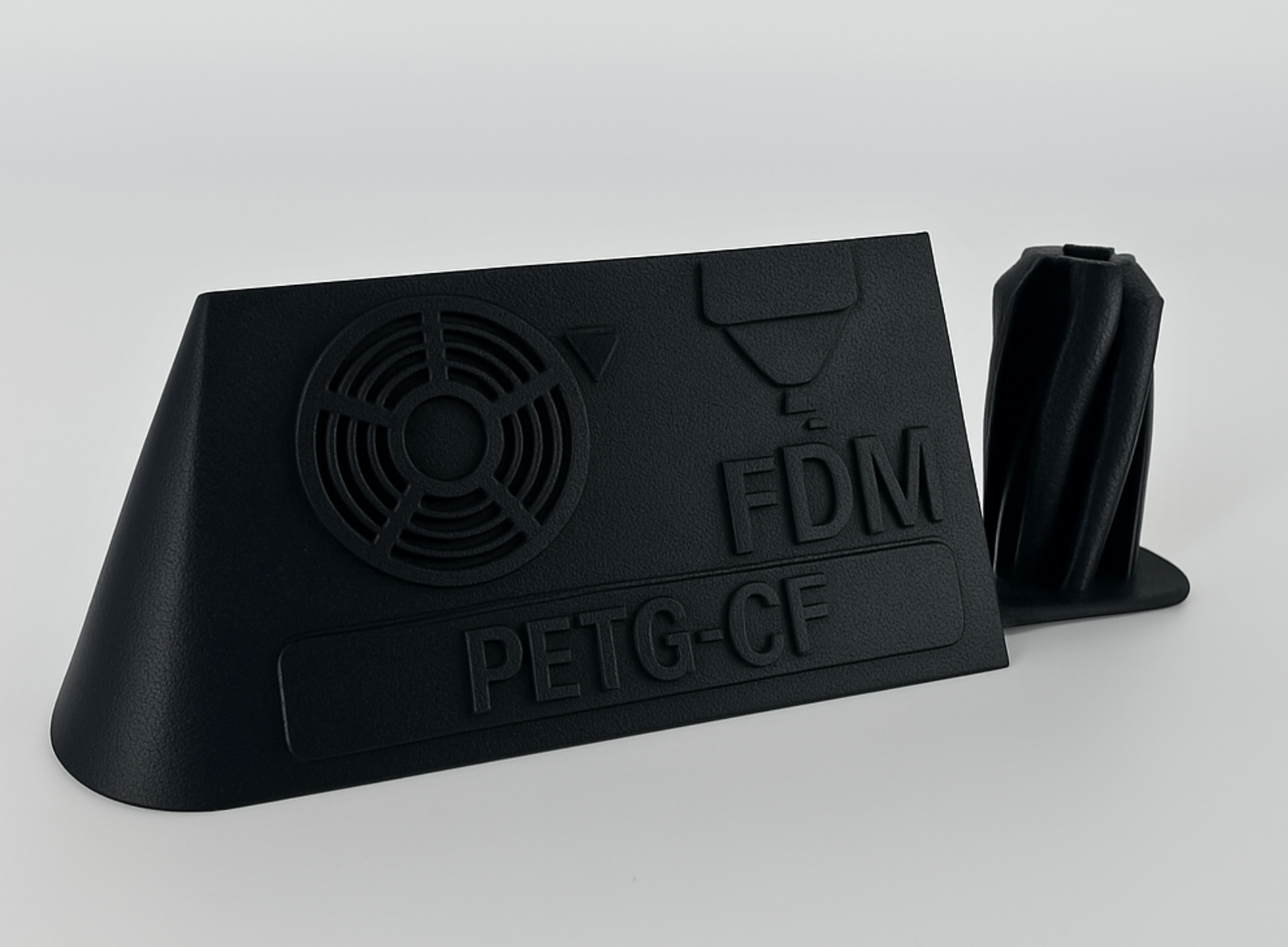

OzFDM PETG-CF Filament

OzFDM's PETG-CF (Polyethylene Terephthalate Glycol + Carbon Fibre) filament combines the toughness and reliability of PETG with the added rigidity, heat resistance, and dimensional stability of carbon fibre reinforcement. The finely chopped fibres increase overall strength while reducing shrinkage, warping, and surface imperfections, resulting in prints that are both durable and visually refined. This advanced blend maintains PETG's signature toughness and chemical resistance while delivering a clean, professional matte finish with a subtle grain texture that highlights the carbon fibres within each layer, giving printed parts a sleek, technical appearance and a premium feel that reflects both strength and precision. PETG-CF performs exceptionally well for functional prototypes, mechanical parts, drone components, and production ready models that demand high impact strength and thermal stability. When paired with a hardened steel nozzle, it offers consistent performance, reliable adhesion, and premium results across a wide range of technical applications.

A single shade designed for performance and professional appeal.

Engineered in Black - PETG-CF Colour Range

PETG-CF is available exclusively in a deep carbon black shade that highlights the fine texture of its embedded fibres. The matte finish provides a sleek, engineered appearance that feels professional and understated, while the dark tone subtly enhances the grain detail created by the carbon fibre blend. This refined surface not only improves the aesthetic of functional prints but also helps mask layer lines and minor imperfections. The result is a filament that delivers both durability and visual balance, ideal for mechanical parts, tools, and production components that need to look as strong as they perform.

Disclaimer on Colour Accuracy: The filament colours displayed above have been specified using online hex code sources and may vary slightly from the actual physical product due to differences in screen calibration, lighting, and digital representation. Please note that this colour range is subject to refinement once our Nix Mini 3 Colour Sensor arrives, allowing us to assess and scan each filament shade in person for greater accuracy.

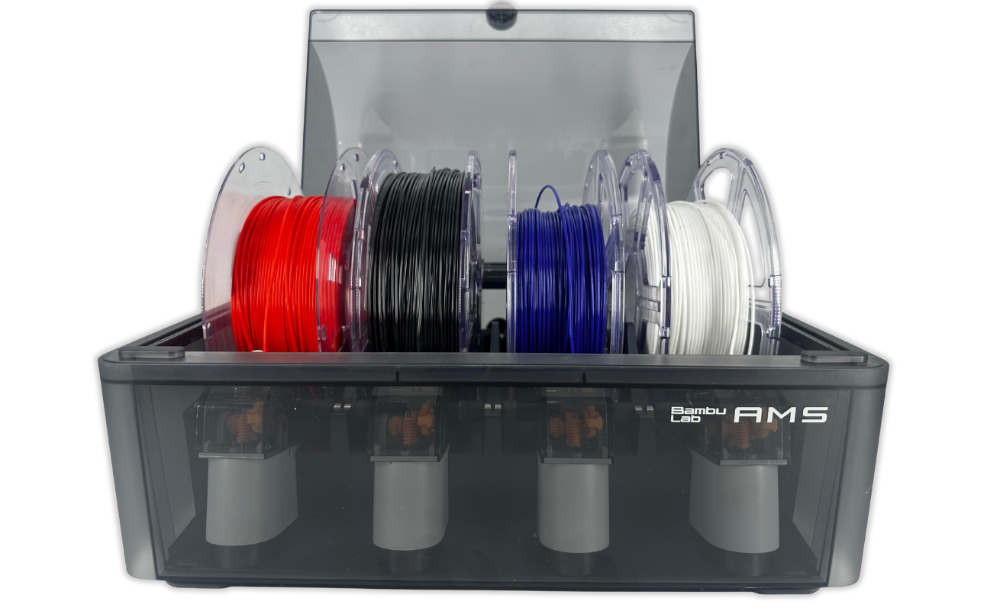

PETG-CF performs well through the AMS when handled with proper care and setup.

AMS Compatible, With Key Considerations

PETG-CF can be used with the Bambu Lab AMS, though extra care and setup considerations are essential to achieve the best results and maintain the integrity of your machine. The standard AMS is compatible, however, AMS Lite is not as its simplified design lacks the durability needed to withstand the rough and abrasive nature of PETG-CF. Due to the filament’s rigid carbon fibre content, continuous use may cause gradual wear on AMS components such as gears and PTFE tubes. To reduce wear, it is recommended to load PETG-CF into a less frequently used AMS slot to help distribute friction evenly across the internal feeding components and minimise the long term strain on gears and tubing. Or you could bypass the AMS machine completely by printing from a side mounted external spool holder, which provides a smoother filament path and removes any content within the AMS's moving parts all together.

Always dry the filament thoroughly before printing, ideally at 70°C for at least 5 hours, to maintain consistent quality and layer adhesion. Proper drying also helps prevent popping, uneven extrusion, and visible surface imperfections during long prints. Drying prevents moisture absorption that can cause bubbling, uneven extrusion, or a rough surface texture. Proper preparation helps PETG-CF retain its smooth flow and dimensional accuracy throughout longer prints When used with a hardened steel nozzle and correct cooling settings, PETG-CF performs smoothly while preserving the reliability of your printing hardware. A moderate fan speed is recommended to balance cooling and adhesion, while overcooling that can weaken layer bonding or cause delamination on larger models.

Performance Reinforced, PETG-CF Filament

Precision Reinforced

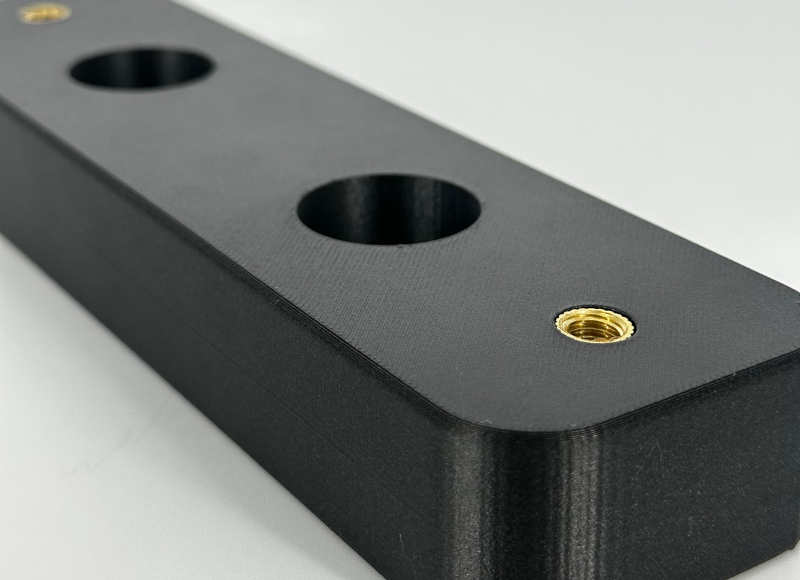

PETG-CF combines the reliability of PETG with the stiffness and dimensional stability of carbon fibre reinforcement. The result is a filament that delivers higher strength, improved temperature resistance, and enhanced layer consistency while maintaining PETG's signature toughness and ease of use.

The carbon fibre particles increase rigidity throughout each layer, allowing printed parts to resist flexing, deformation, and surface distortion even under mechanical load or elevated heat.

It prints with low shrinkage and minimal warping, making it ideal for precise, functional components that need to perform under pressure and need to maintain dimensional accuracy over time.

The surface finish has a subtle matte texture that adds a refined, technical look to every print, offering both the visual appeal and performance reliability expected from professional grade materials.

Performance You Can Trust

The addition of carbon fibre gives PETG-CF exceptional rigidity and mechanical endurance, allowing parts to hold their form under load and heat. This reinforcement enhances structural stability across complex geometries, reducing flex and deformation even during prolonged mechanical stress or elevated temperatures.

The carbon fibre also distributes internal forces more evenly, giving printed parts a balanced strength that rivals many engineering grade materials while maintaining PETG’s reliability and print consistency.

Its enhanced layer adhesion and stable flow reduce the chance of warping or deformation, even in larger prints. This combination of strength and consistency makes PETG-CF perfect for tools, jigs, brackets, and mechanical housings that need long-term reliability.

While slightly more advanced to print than standard PETG, it rewards careful setup with worthwhile results that remain stable across demanding applications.

Built for Real World Projects

From replacement components and structural prototypes to drone frames, racing models, and protective enclosures, PETG-CF is built for projects where durability meets design precision.

Its advanced blend of high stiffness, impact strength, and thermal resistance allows it to perform consistently in demanding environments where standard PETG may soften, flex, or lose structural integrity under heat.

The finely dispersed carbon fibres reinforce each layer, providing greater stability and resistance to fatigue, even in parts subject to vibration or continuous load. The matte, carbon-infused surface delivers a clean, technical aesthetic that masks layer lines, enhances surface quality, and reduces the need for post processing.

For makers and engineers seeking dependable, production ready results, PETG-CF delivers the ideal combination of strength, precision, and visual refinement, a material engineered to look professional and perform flawlessly over time.

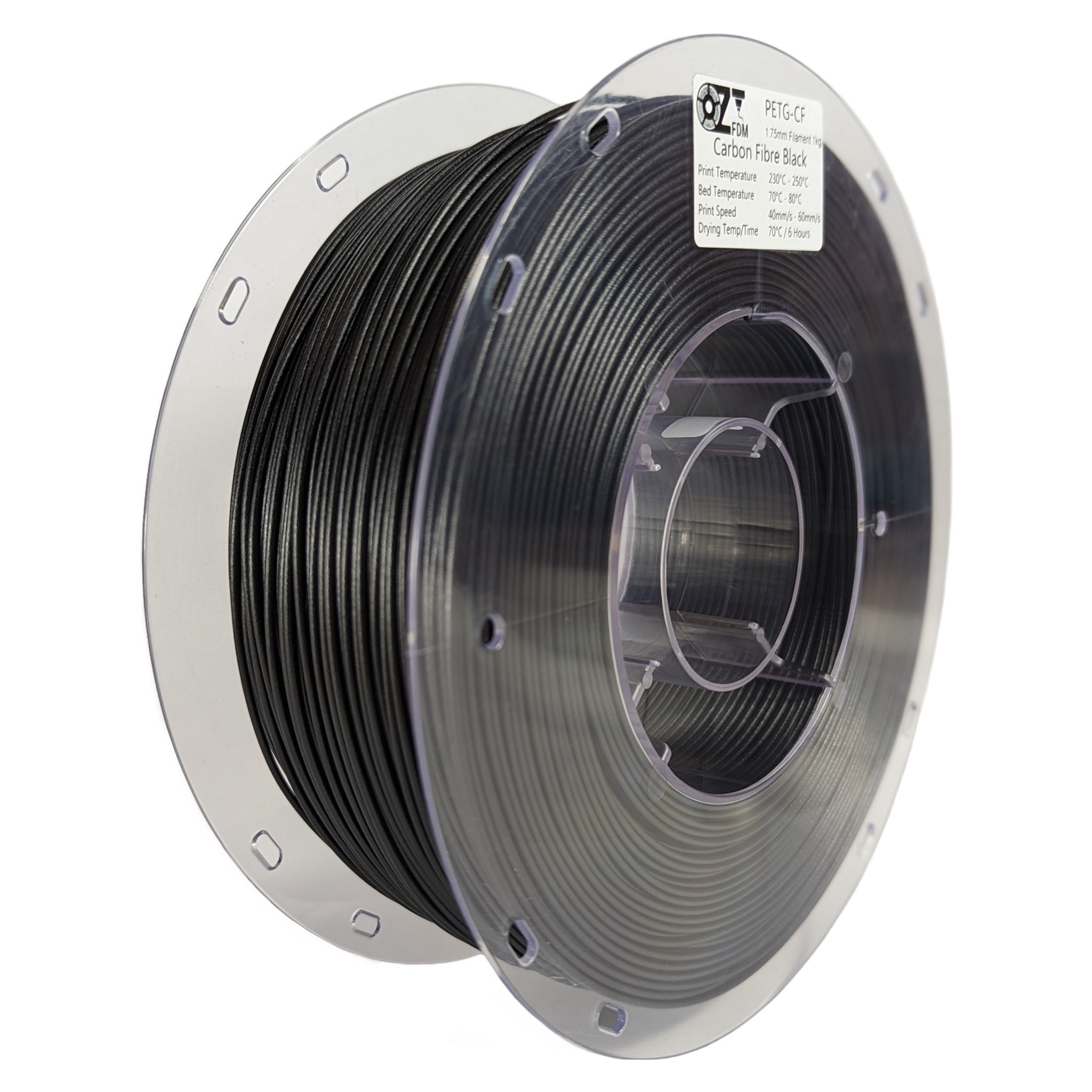

PETG-CF Technical Specifications

Each spool of OzFDM’s premium PETG-CF filament is securely vacuum-sealed with a moisture-absorbing desiccant to maintain optimal print quality right up to that special moment you open the box.

Every package includes recommended printing and drying settings, ensuring you achieve smooth, consistent results right from your first layer.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.05mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

70°C for a minimum of 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

PETG-CF is designed for reliable extrusion, strong layer bonding, and dimensional accuracy. The carbon fibre reinforcement improves print stability and finish quality while reducing shrinkage on larger models. Use a hardened steel nozzle, moderate cooling, and thoroughly dried filament for best results. When tuned correctly, PETG-CF prints clean, strong, and ready for everyday use straight off the build plate.

For best results, follow the recommended print parameters provided below to achieve reliable, high-quality prints every time.

Nozzle temperature

230°C - 250°C (240°C is recommended)

Bed temperature

50°C - 80°C

Printing speed

40mm/s - 60mm/s (40mm/s recommended)

Support material

PETG-CF (Self supported)

OzFDM's PETG-CF offers exceptional rigidity, tensile strength, and layer adhesion thanks to its carbon fibre reinforcement. It maintains dimensional accuracy under load, making it ideal for durable, lightweight parts that need long-term performance.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

40~43 Mpa

Elongation at Break

ISO 527

7.5~8.5 %

Flexural Modulus

ISO 527

2100~2400 Mpa

Flexural Strength

ISO 178

75~85 Mpa

Impact Strength

ISO 180

3~3.5 KJ/m²

With low shrinkage and consistent extrusion, PETG-CF produces accurate prints with a premium matte finish. The carbon fibre reduces weight and enhances stability, ensuring smooth, refined surfaces across every print.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.27~1.28 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

10~15 g/10min

Moisture Absorption (23°C/24h)

ISO 62

<0.8 %

Our filament withstands elevated temperatures without losing strength or shape. Its reinforced composition increases heat deflection and maintains interlayer bonding, ensuring reliable results in warm or enclosed environments.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

70 °C

Continuous Use Temperature

IEC 60216

80 °C