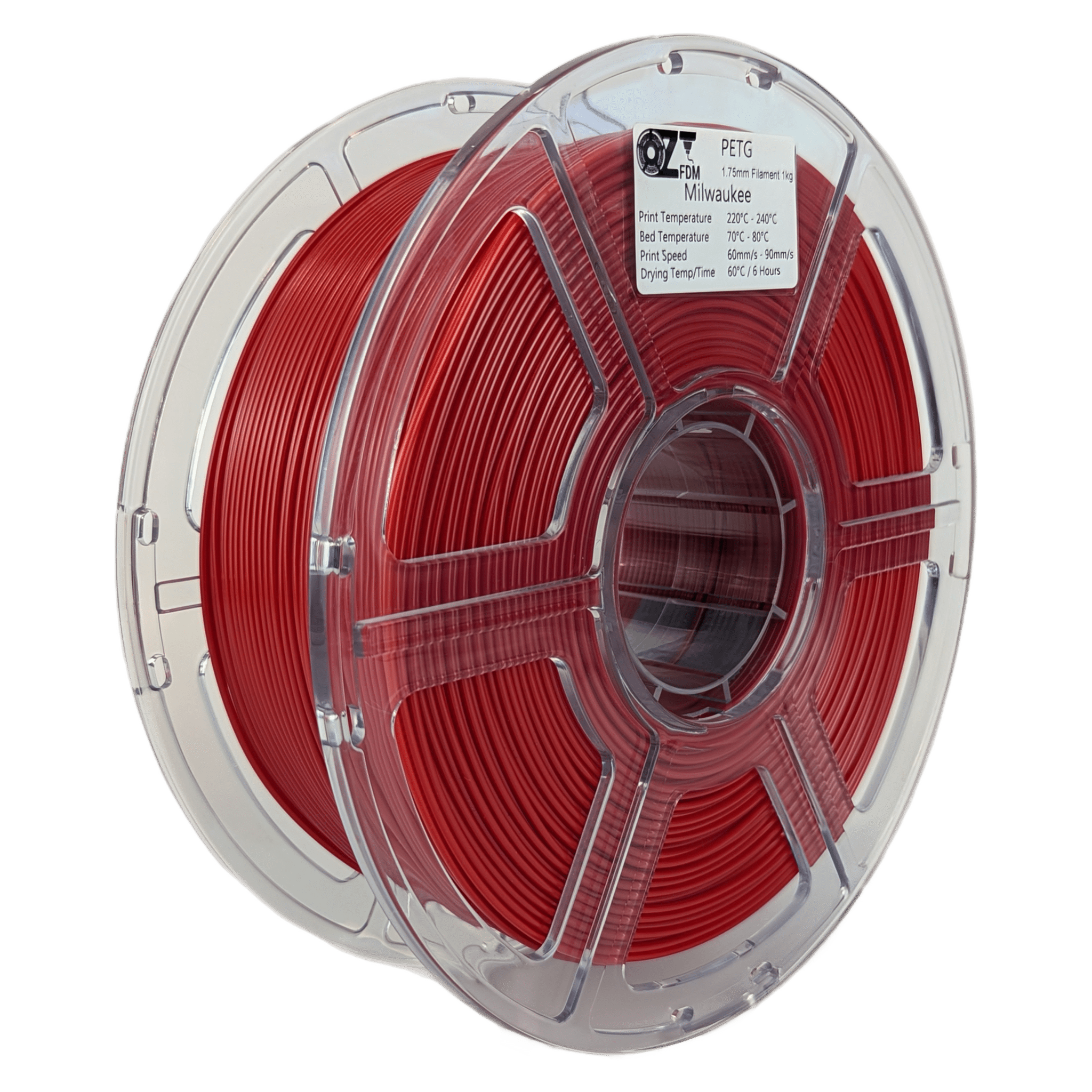

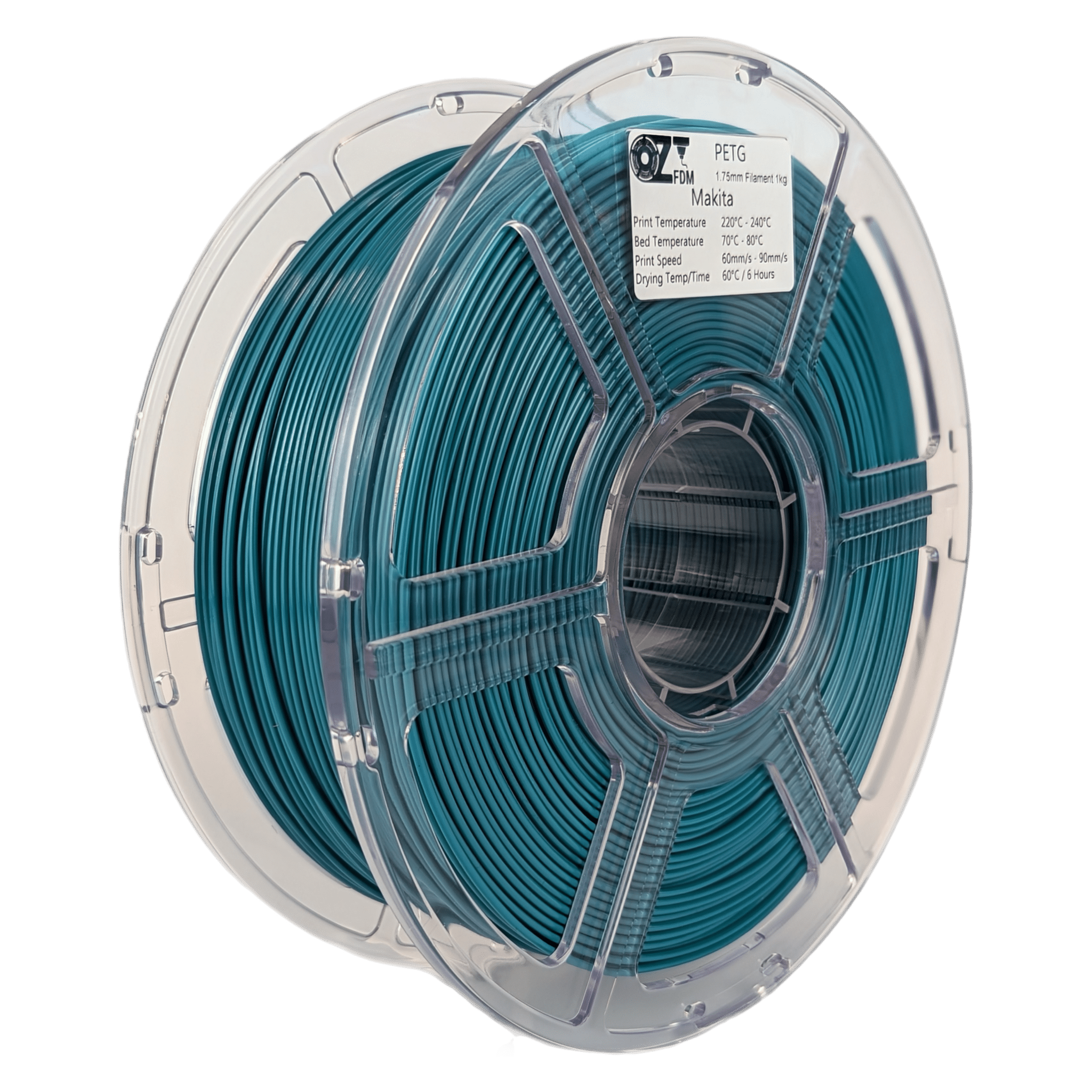

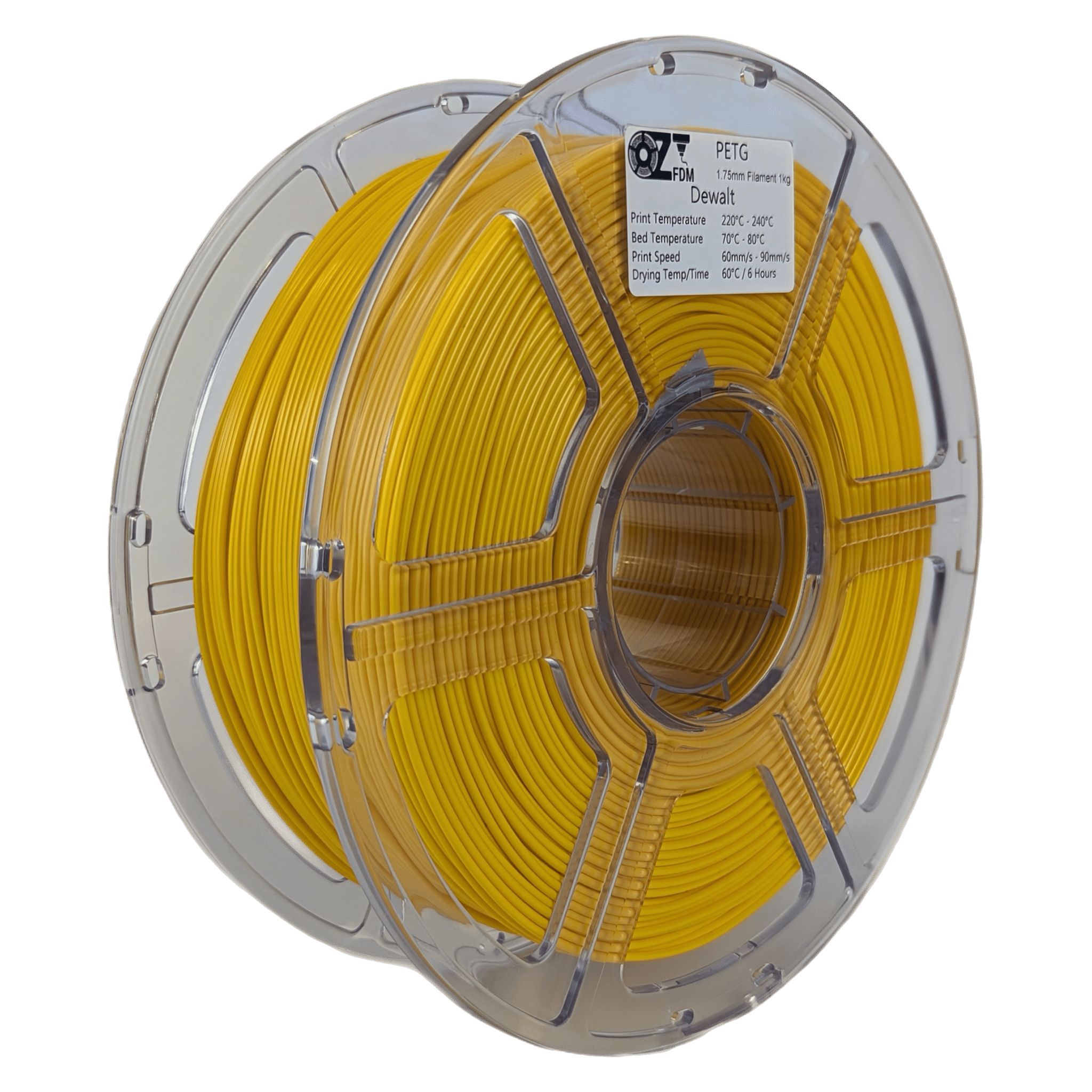

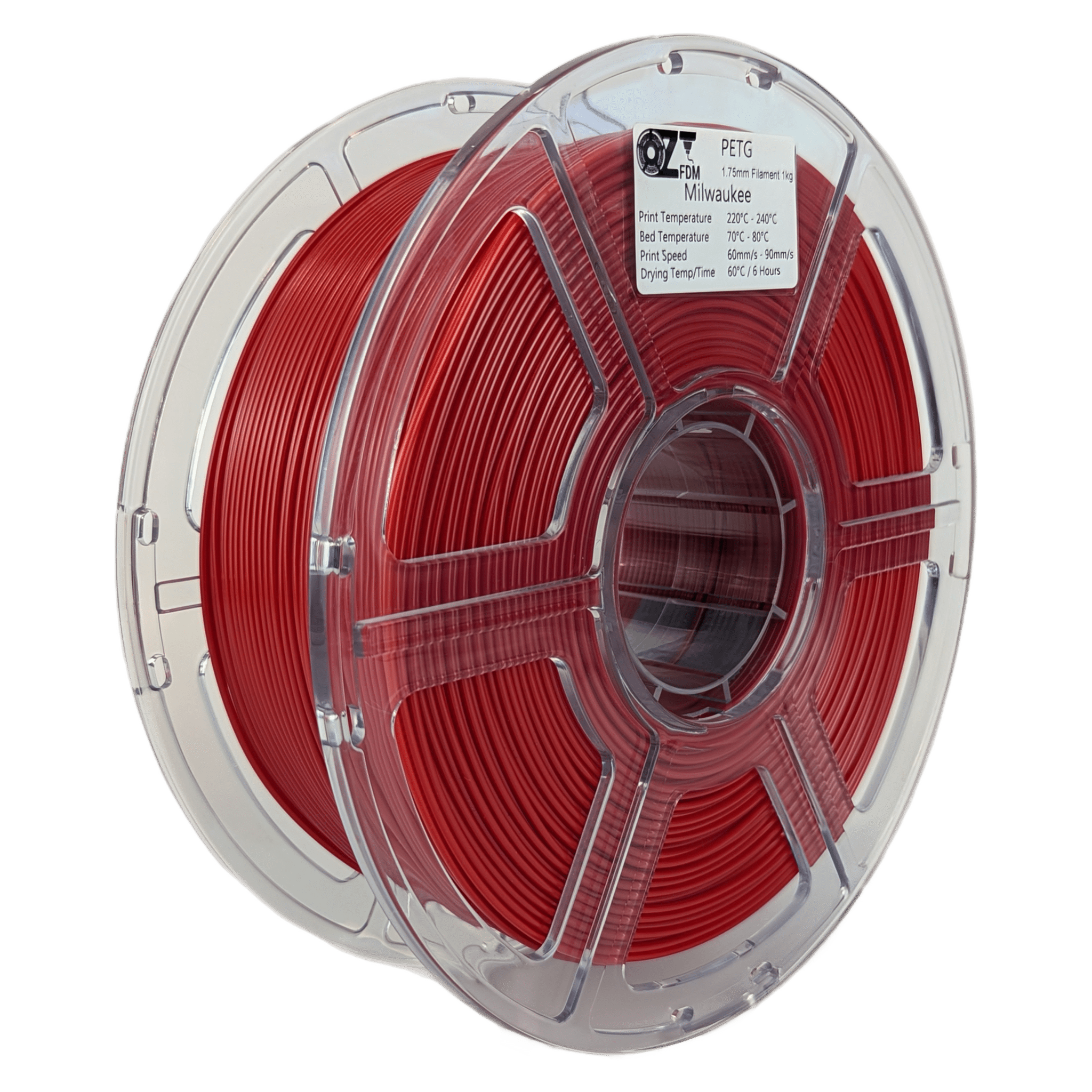

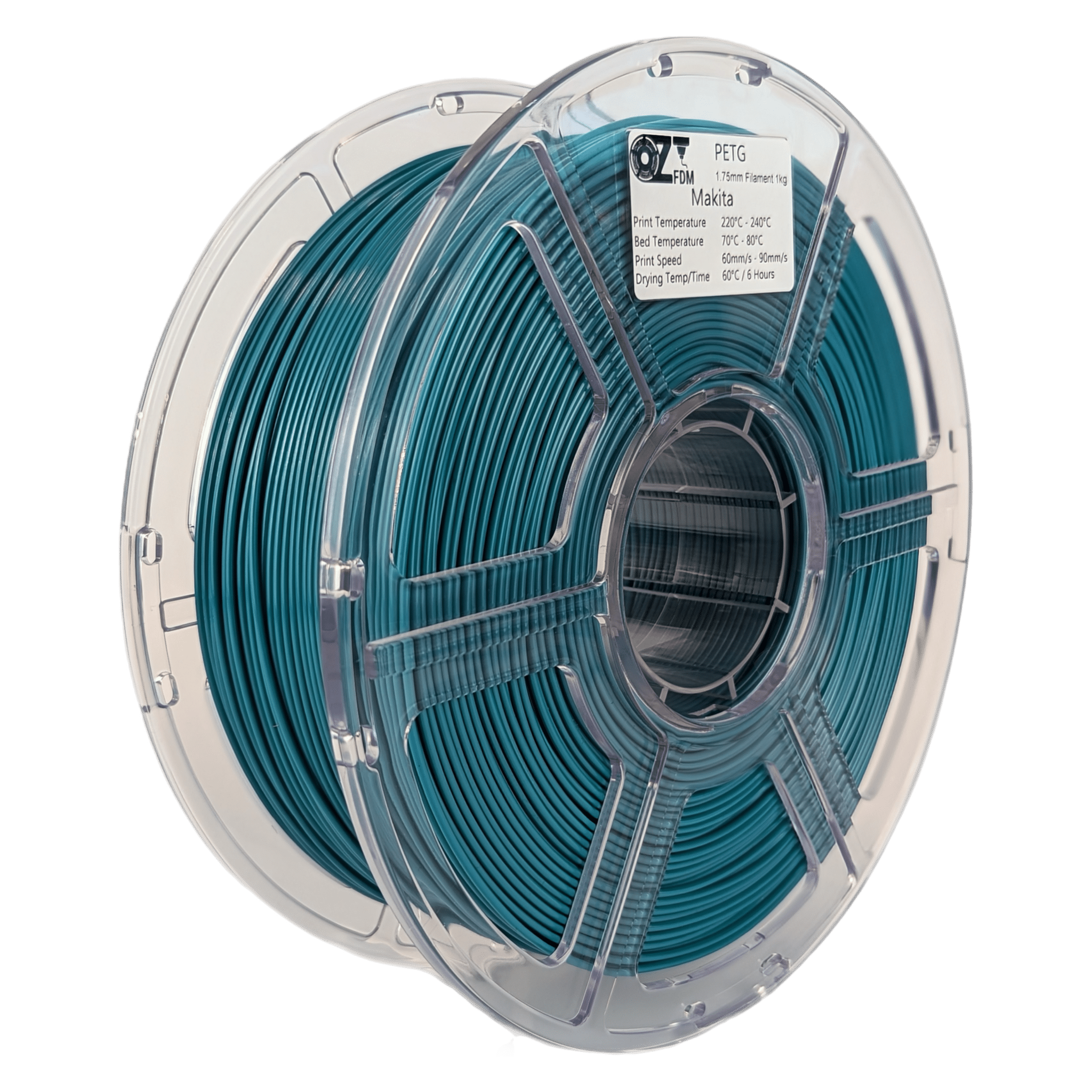

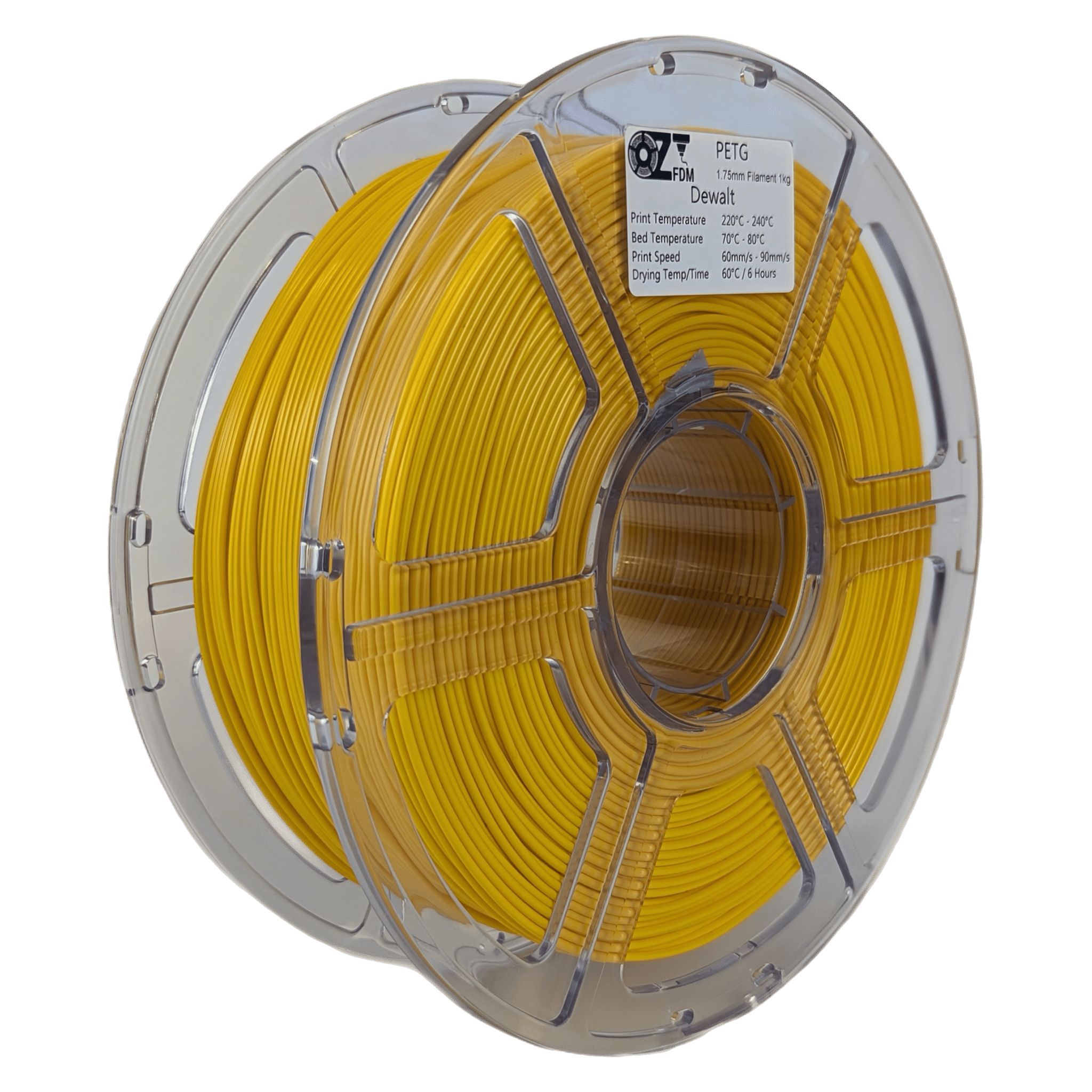

1.75 mm PETG Tool Colours Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

OzFDM PETG+ filament is made from high quality specially modified PETG material. This offers low warping, non-cracking and low print and bed temperatures, making it easier to print than standard PETG while still maintaining its high strength and heat resistance.

Improved Formula for Less oozing, warping and cracking. Water resistant.

Colours are inspired by, but not associated with, global tool companies like Milwaukee, Makita and Dewalt.

The colour match is as close as possible but printing temperatures and speed settings can influence the printed outcome.

Product specifications:

| Filament weight | 1KG |

| Filament diameter | 1.75mm |

| Dimensional tolerance | ±0.03mm |

| Spool weight (empty) | 150g |

| Spool weight (new) | 1.15KG |

| Spool diameter outer | 200mm |

| Spool diameter inner (hub) | 52mm |

| Spool width | 65mm |

| Package weight | 1.3KG |

| Package dimensions | 210mm x 210mm x 75mm |

Print parameters:

| Nozzle temperature | 220°C - 240°C |

| Bed temperature | 50°C - 80°C |

| Printing speed | 40mm/s - 60mm/s |

| Support material | PVA , PLA (as support interface) |

Physical Properties:

| Density | ISO 1183 | 1.27~1.28 g/cm3 |

| MFR(250°C/2.16Kg) | ISO 1133 | 4~6 g/10min |

| Moisture Absorbtion(23°C/24h) | ISO 62 | <0.2 % |

Mechanical Properties:

| Tensile Strength | ISO 527 | 41~45 Mpa |

| Elongation at Break | ISO 527 | 10~12 % |

| Flexural Modulus | ISO 527 | 1400~1500 Mpa |

| Flexural Strength | ISO 178 | 64~66 Mpa |

| Impact Strength | ISO 180 | 5~6 KJ/m² |

Thermodynamic Properties:

| HDT @ 0.455 Mpa(66 psi) | ISO 75 | 74 °C |

| Continuous Use Temperature | IEC 60216 | 70 °C |

Drying recommendation:

70°C for a minimum of 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.