Threaded Inserts (Knurled Brass Threaded Heat Insert)

Tax included. Shipping calculated at checkout

Product Features

- High quality Brass inserts

- Sold individually

- Sizes available suit most 3D print files available

Bulk Discounts

- Order 100 Inserts per size and get 10% off

- Order over 1000 Inserts total and get 20% off

Choose options

Knurled Brass Threaded Heat Insert

OzFDM Threaded Inserts

When strength and precision matter, OzFDM’s Knurled Brass Threaded Heat Inserts provide the perfect solution for embedding strong, reusable metal threads into 3D-printed parts.

Engineered for reliability and performance, these inserts are designed to withstand repeated use, giving your prints the professional durability they deserve.

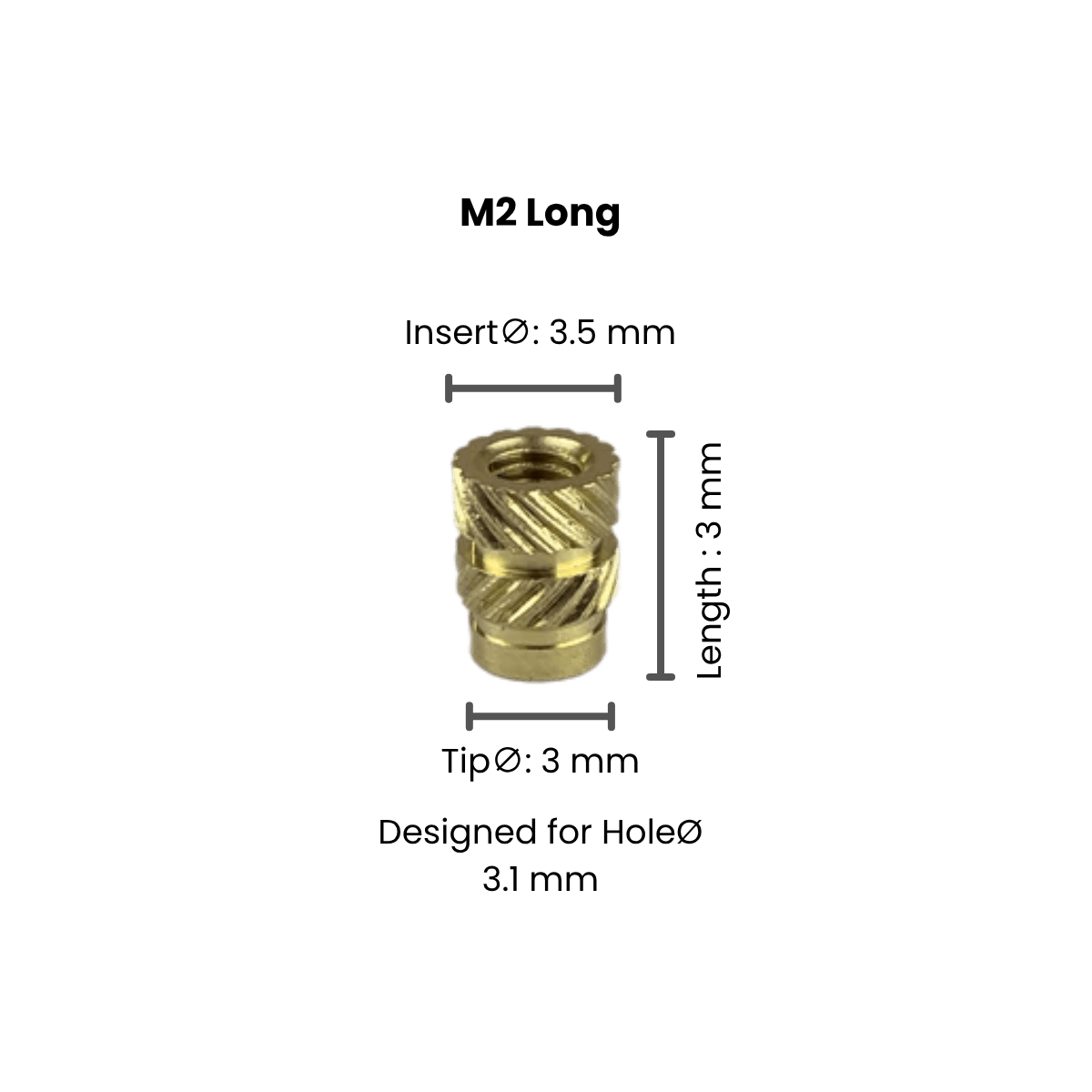

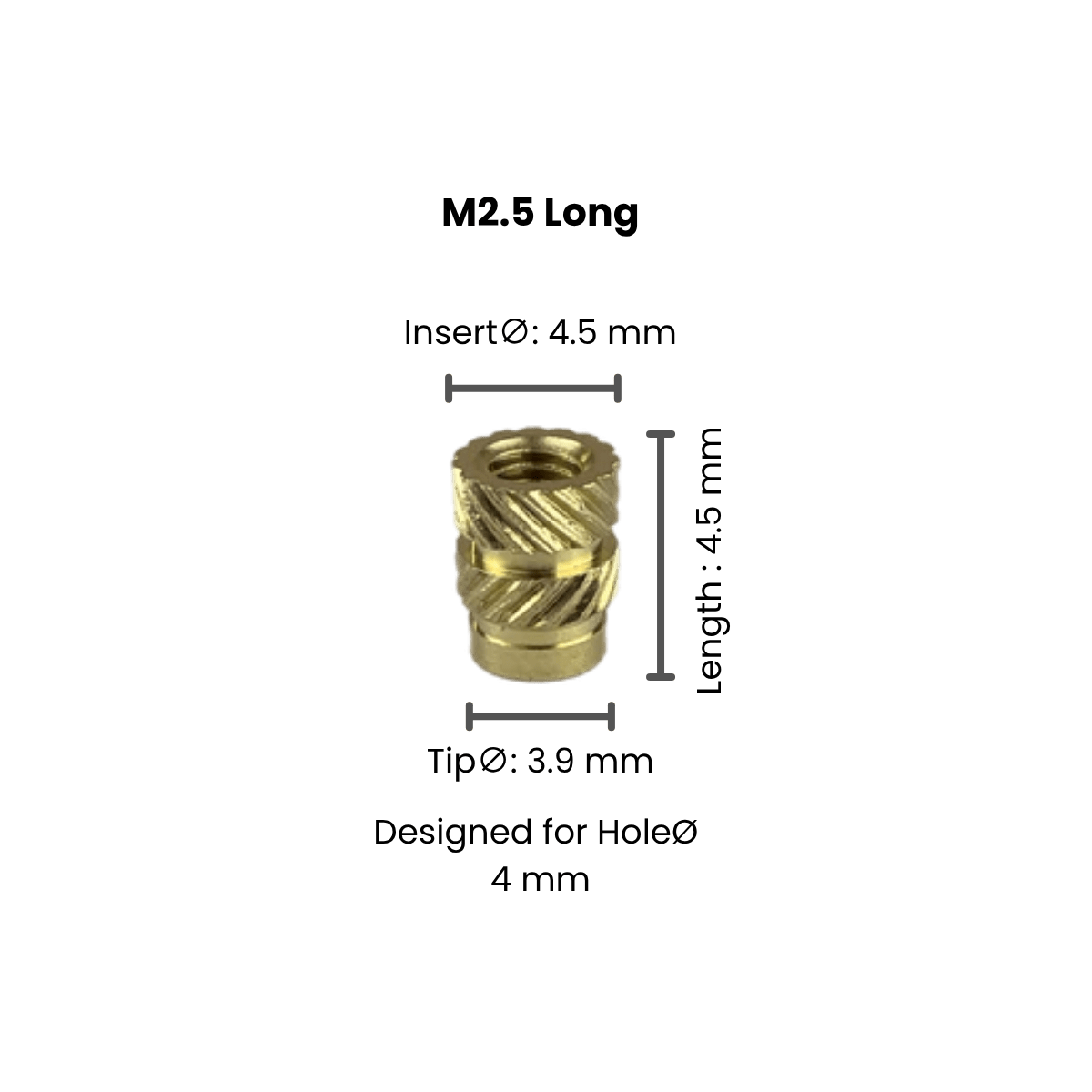

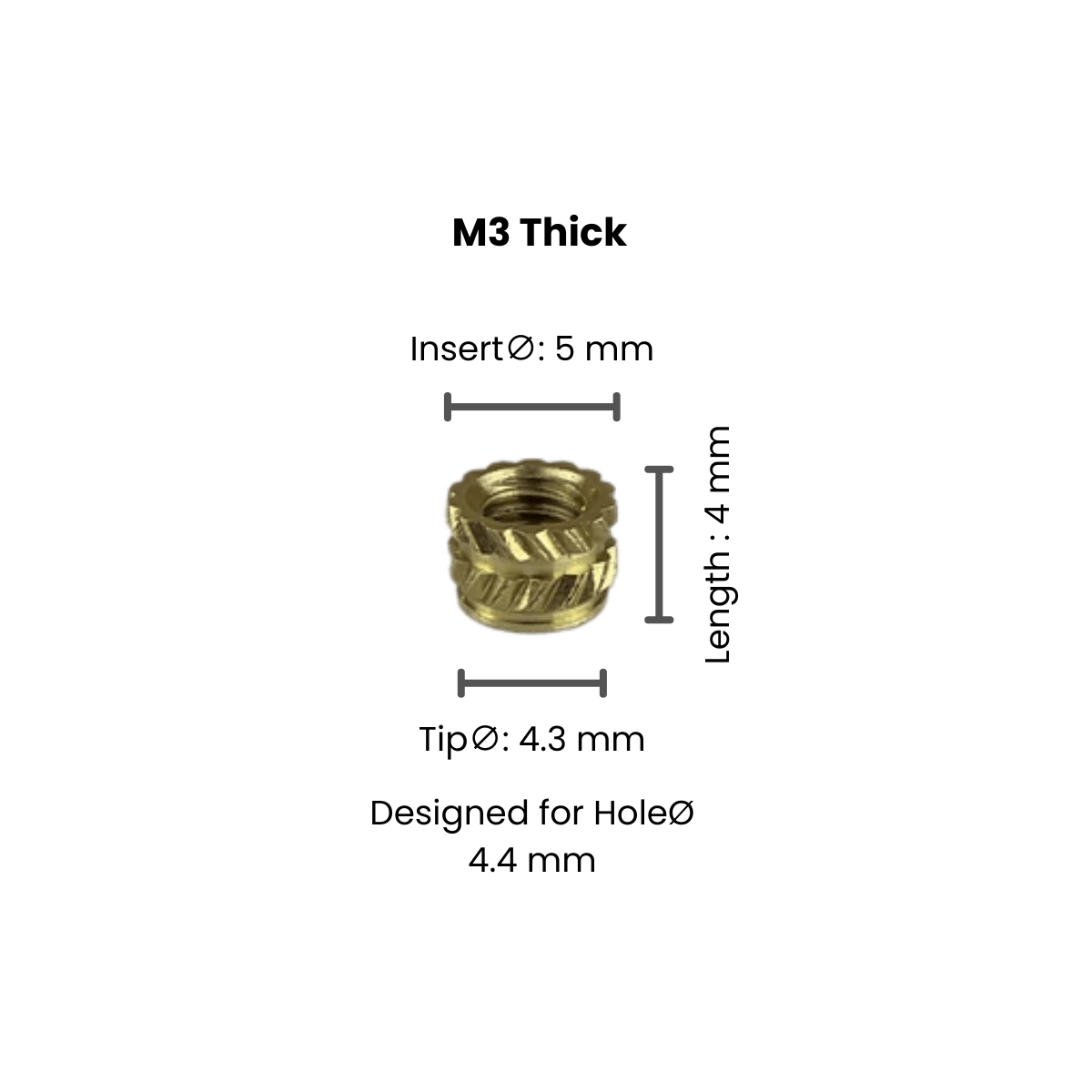

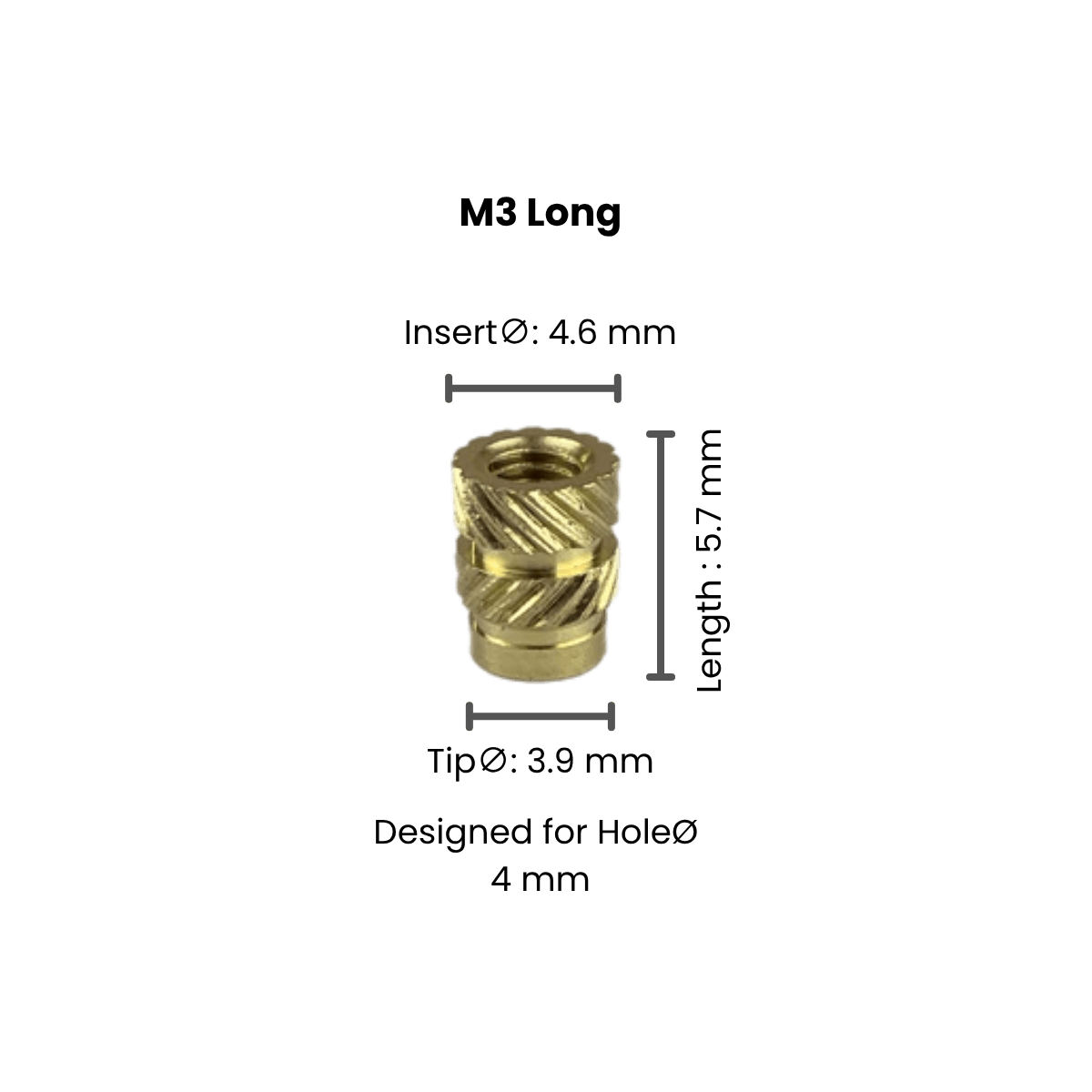

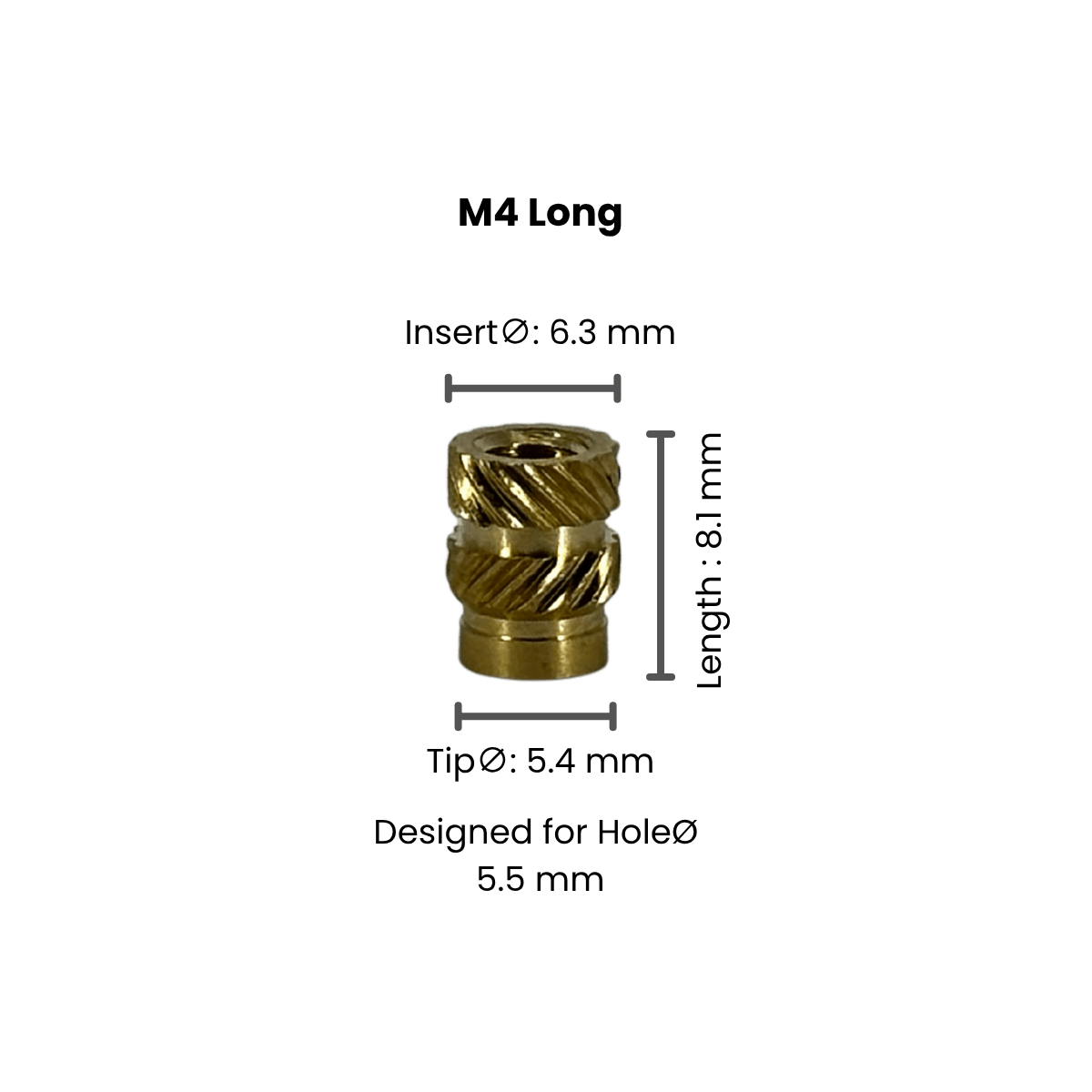

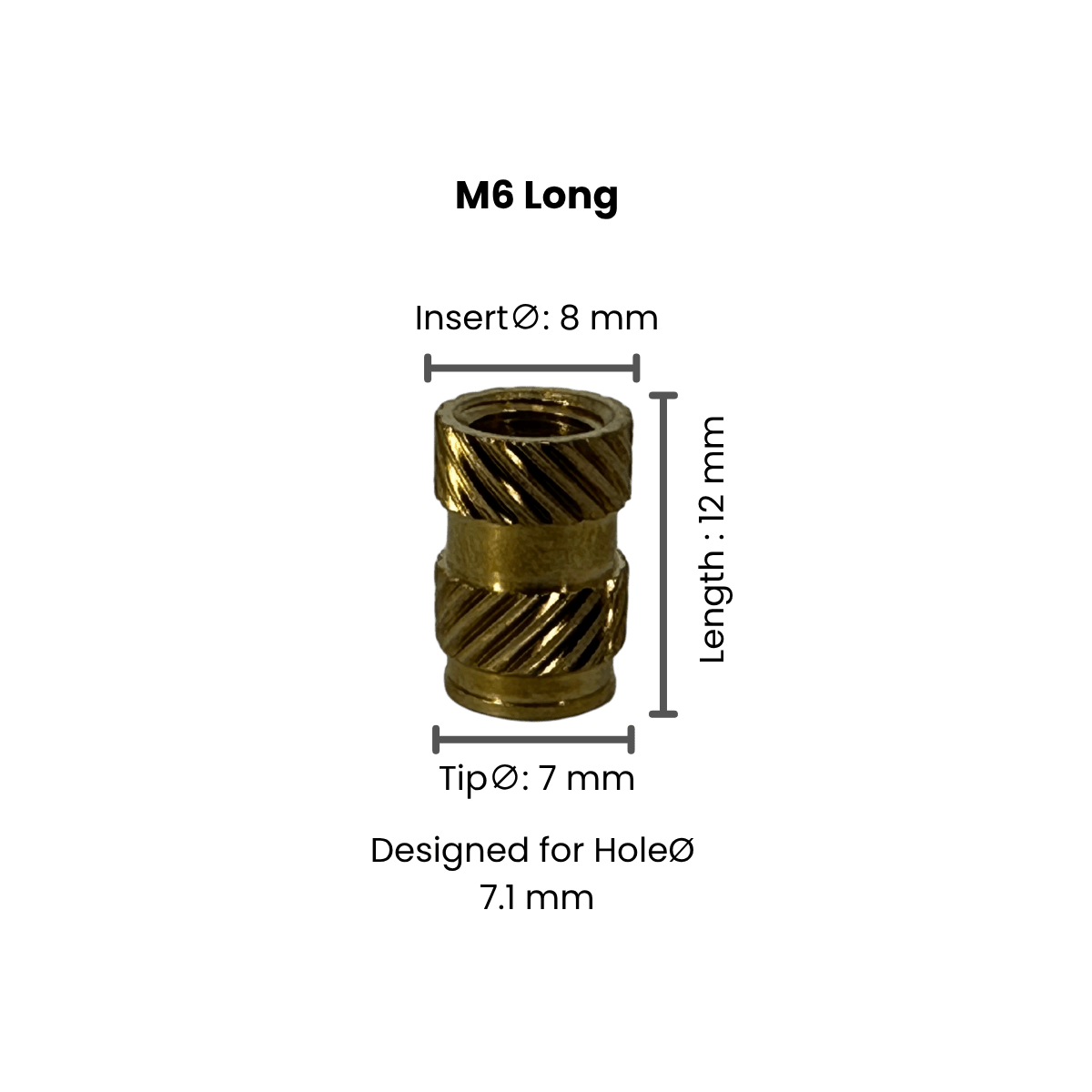

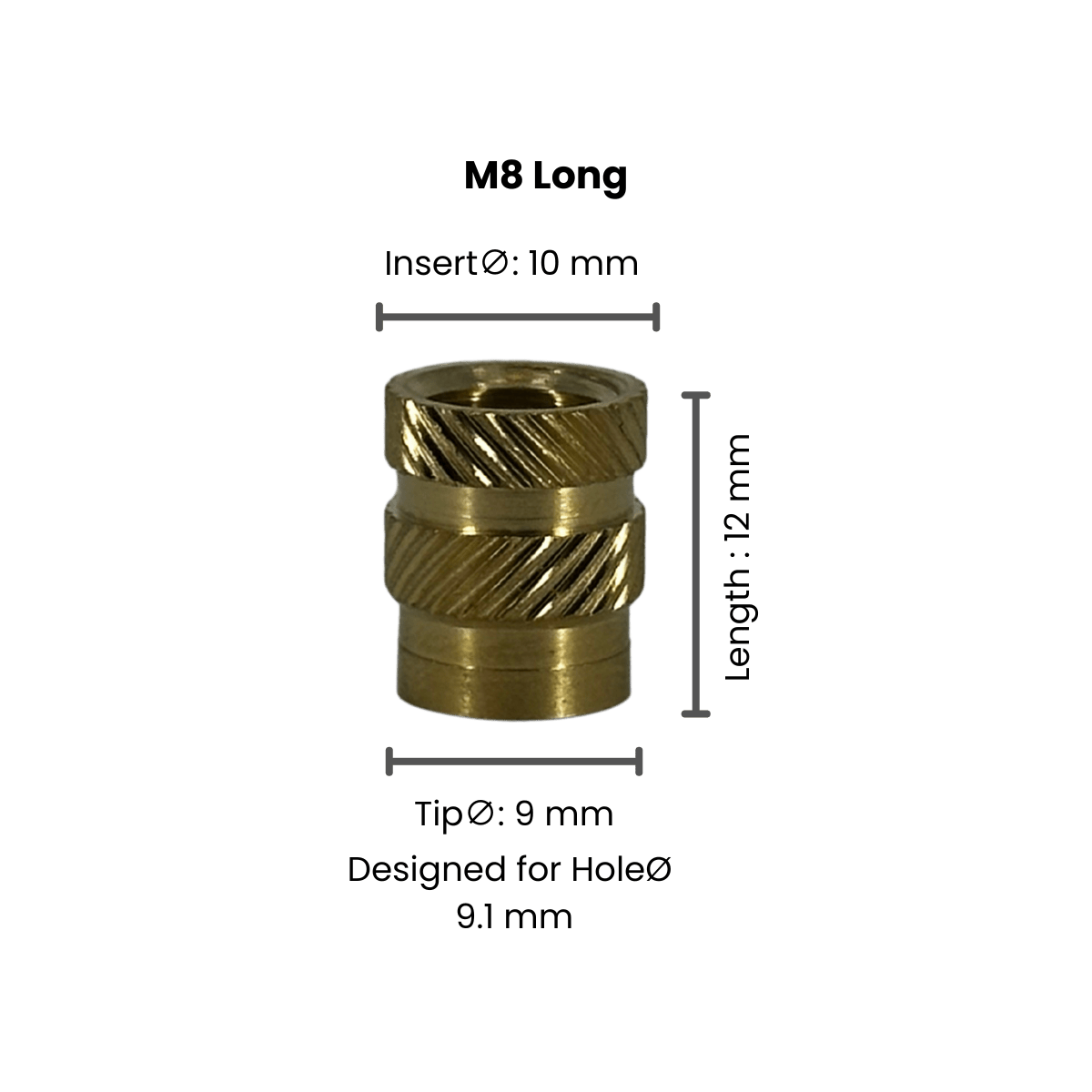

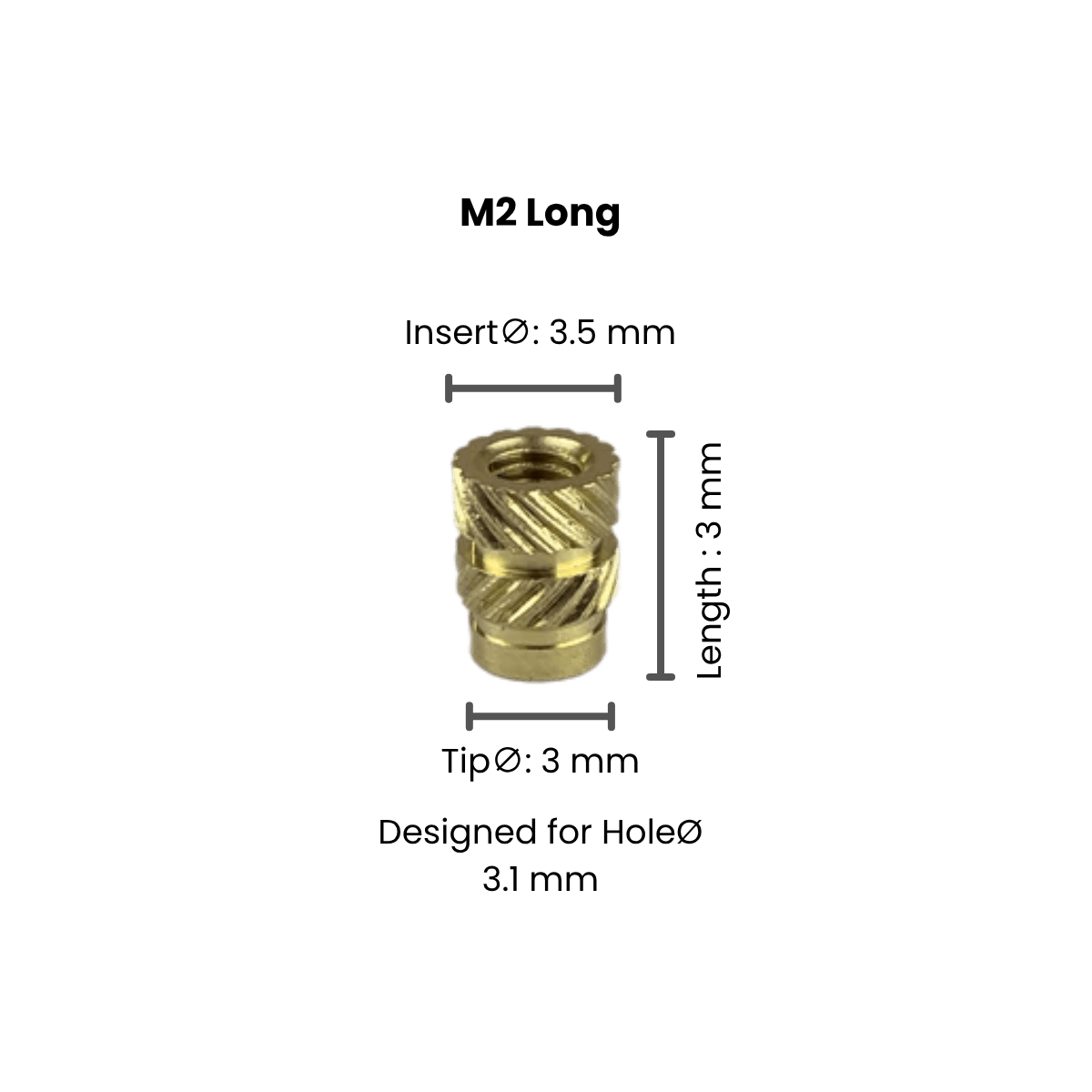

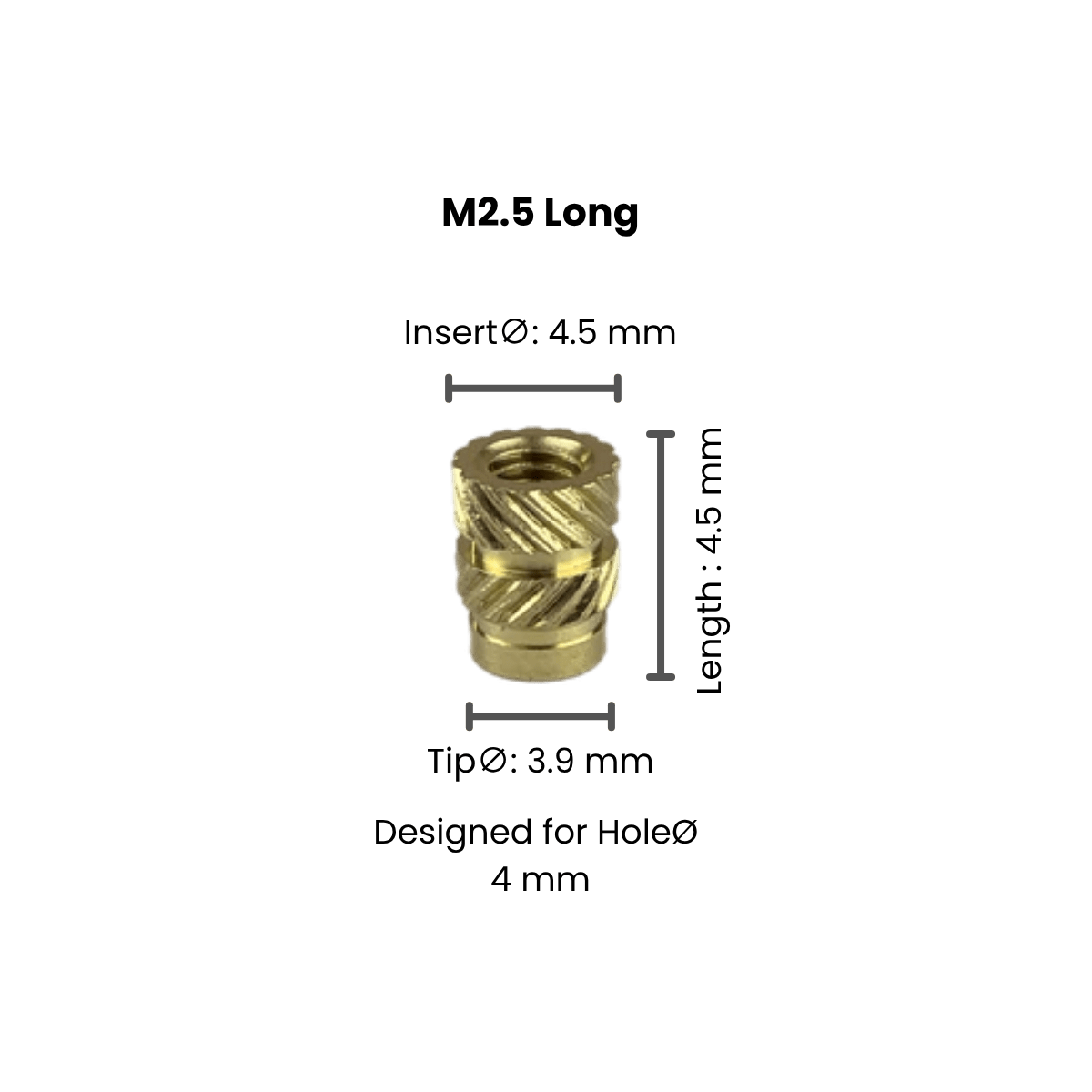

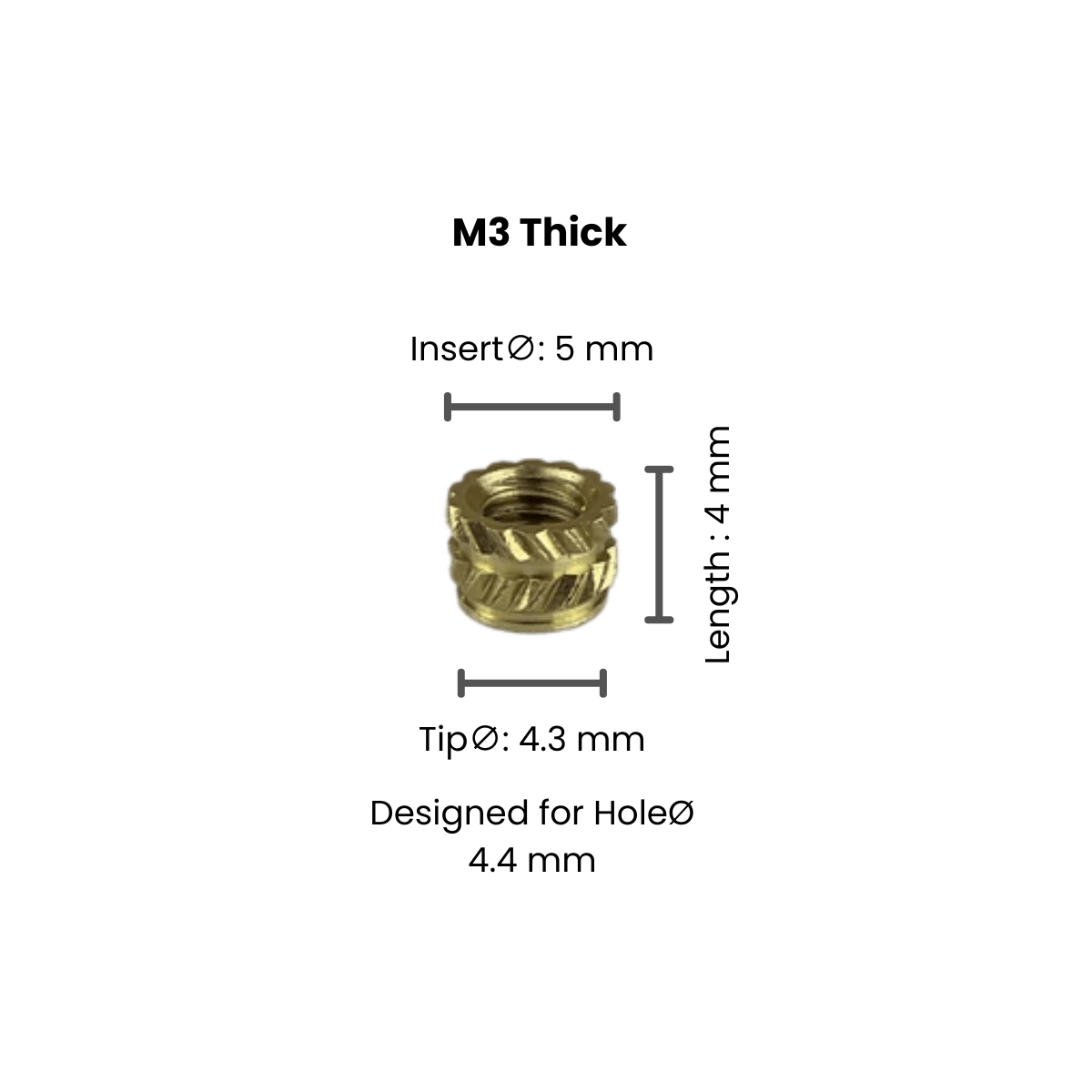

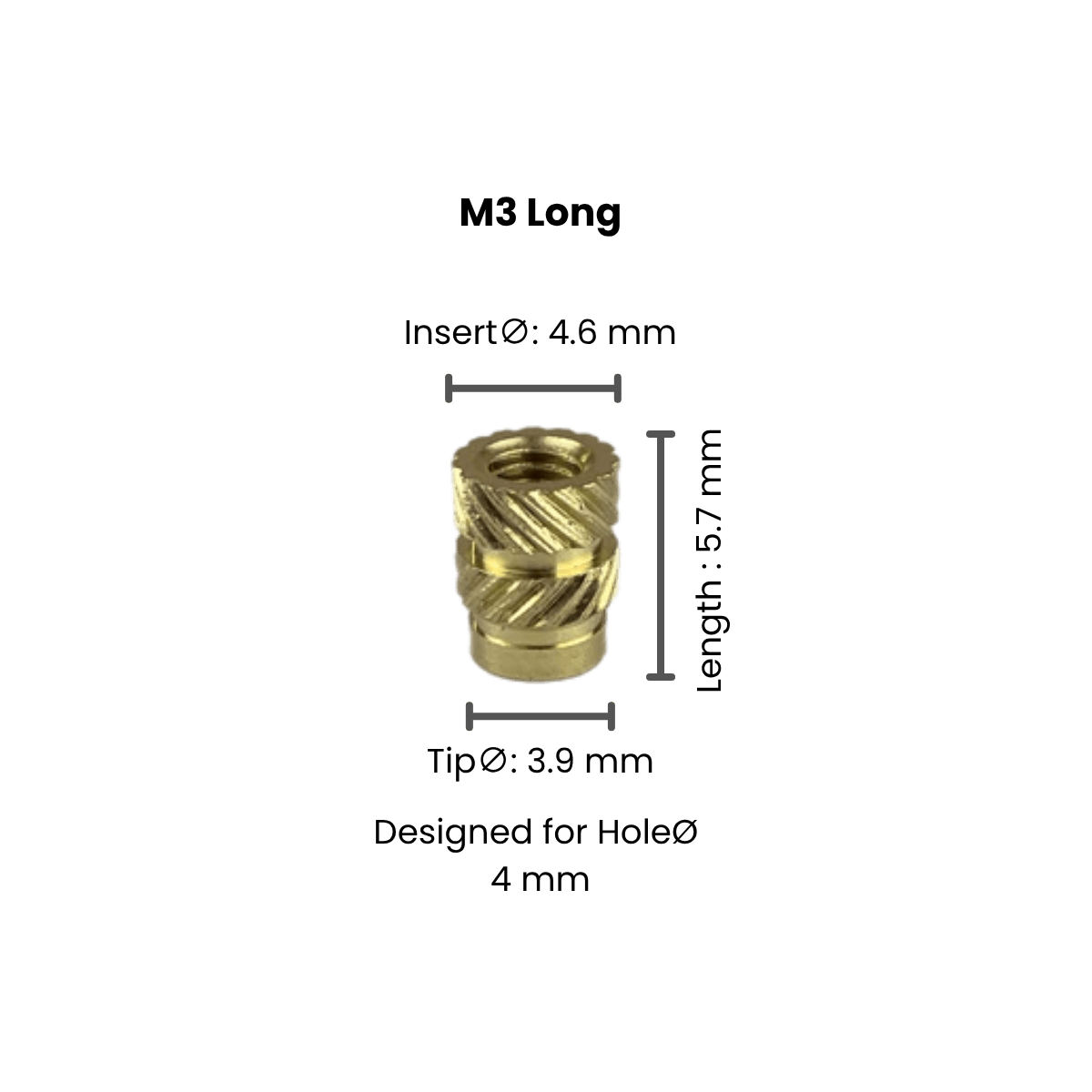

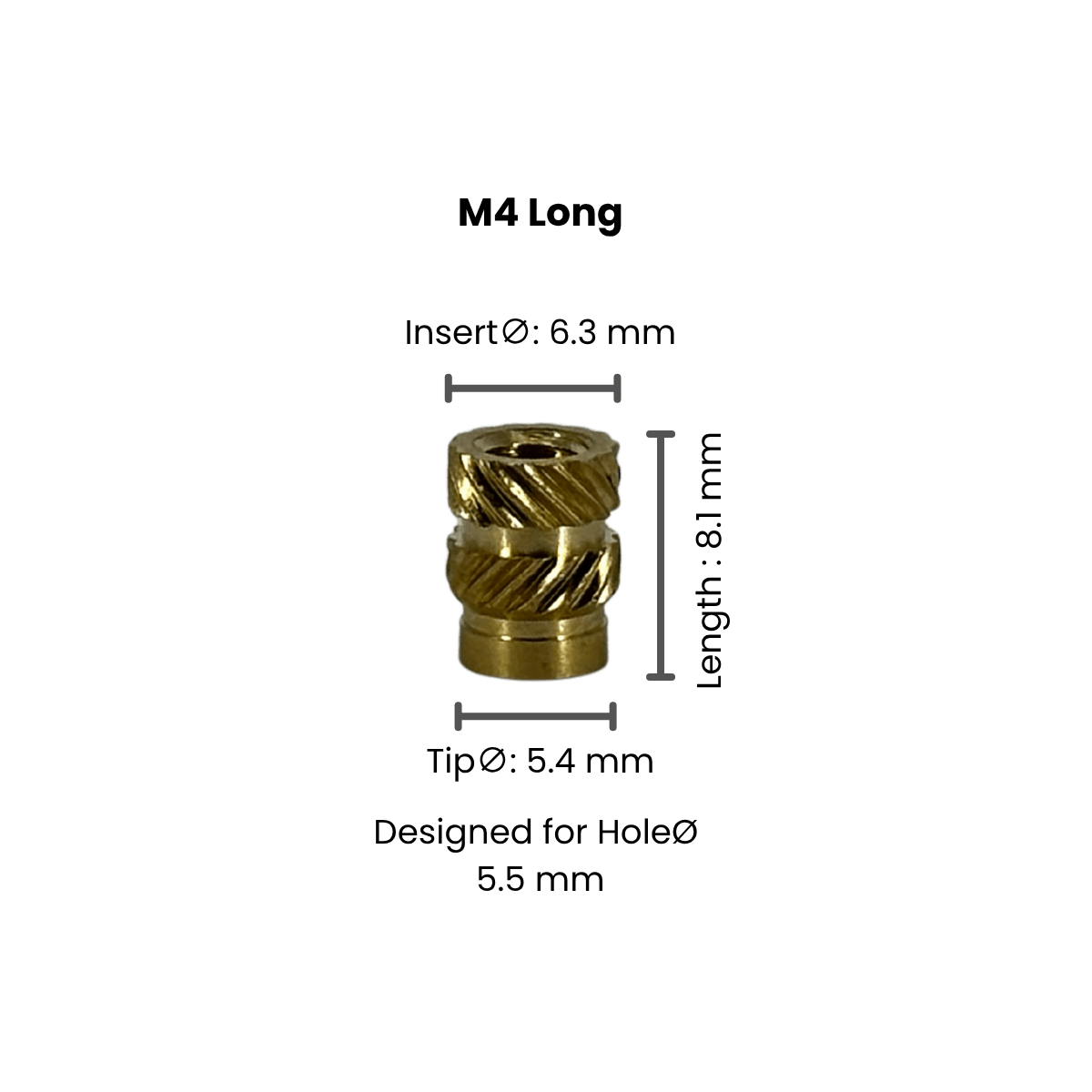

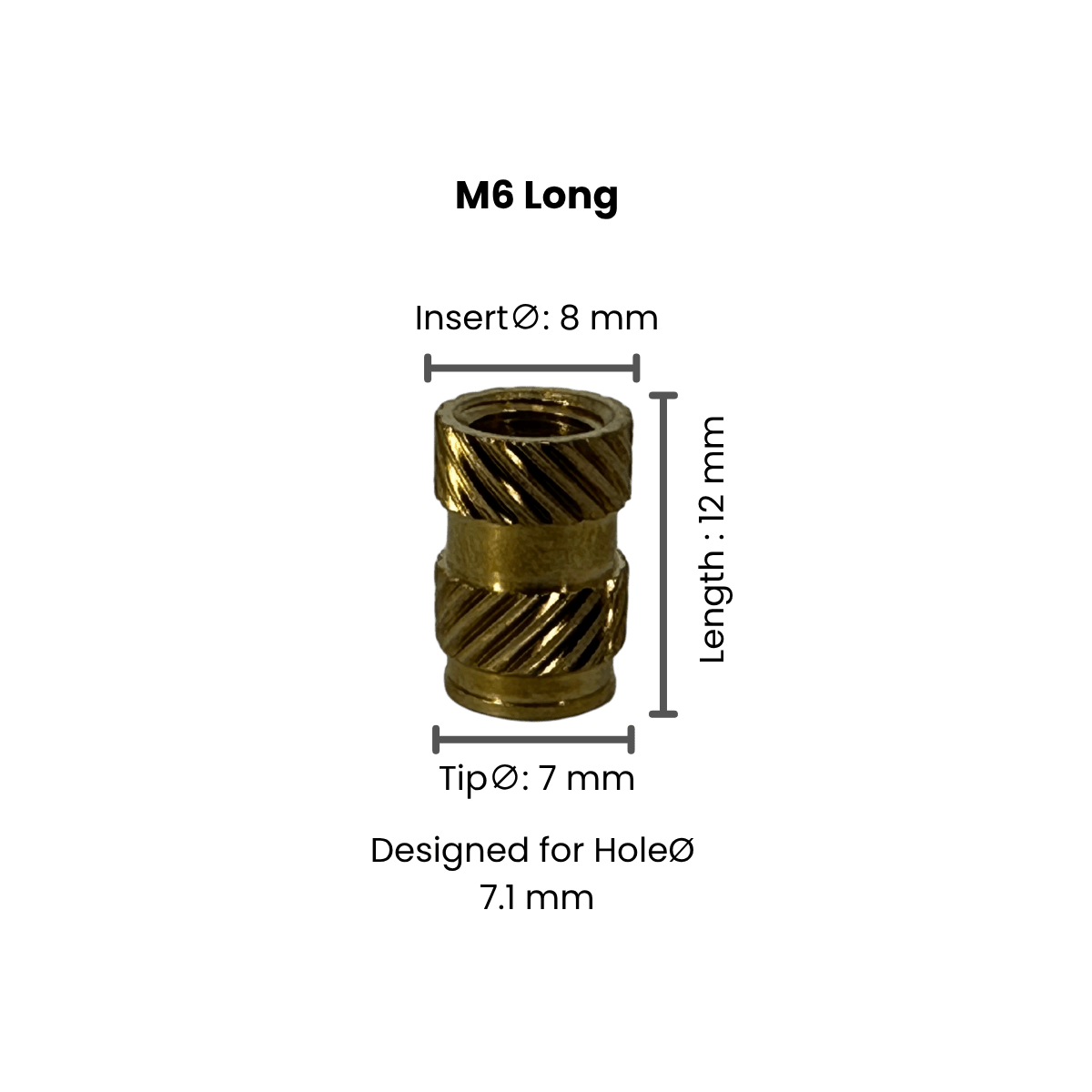

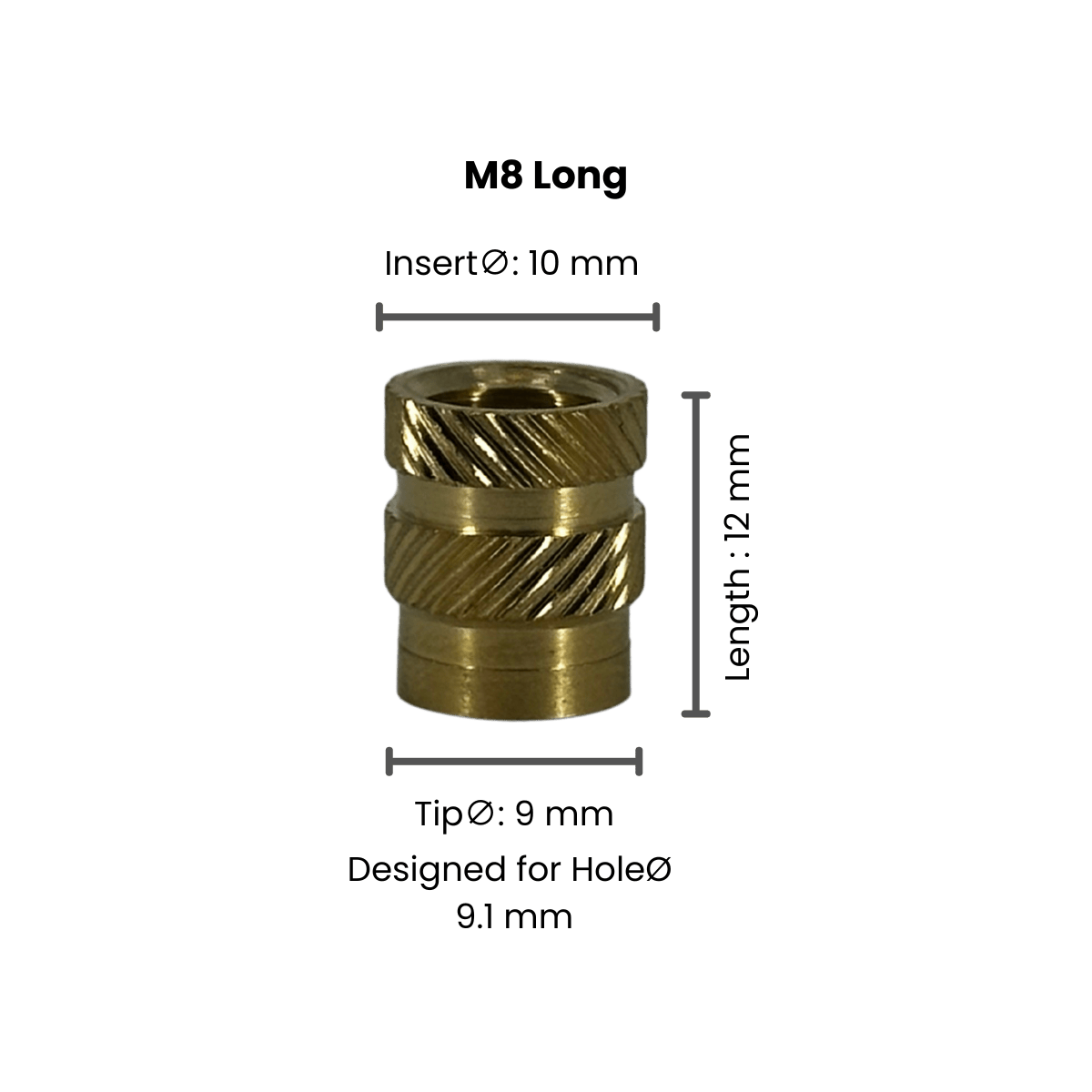

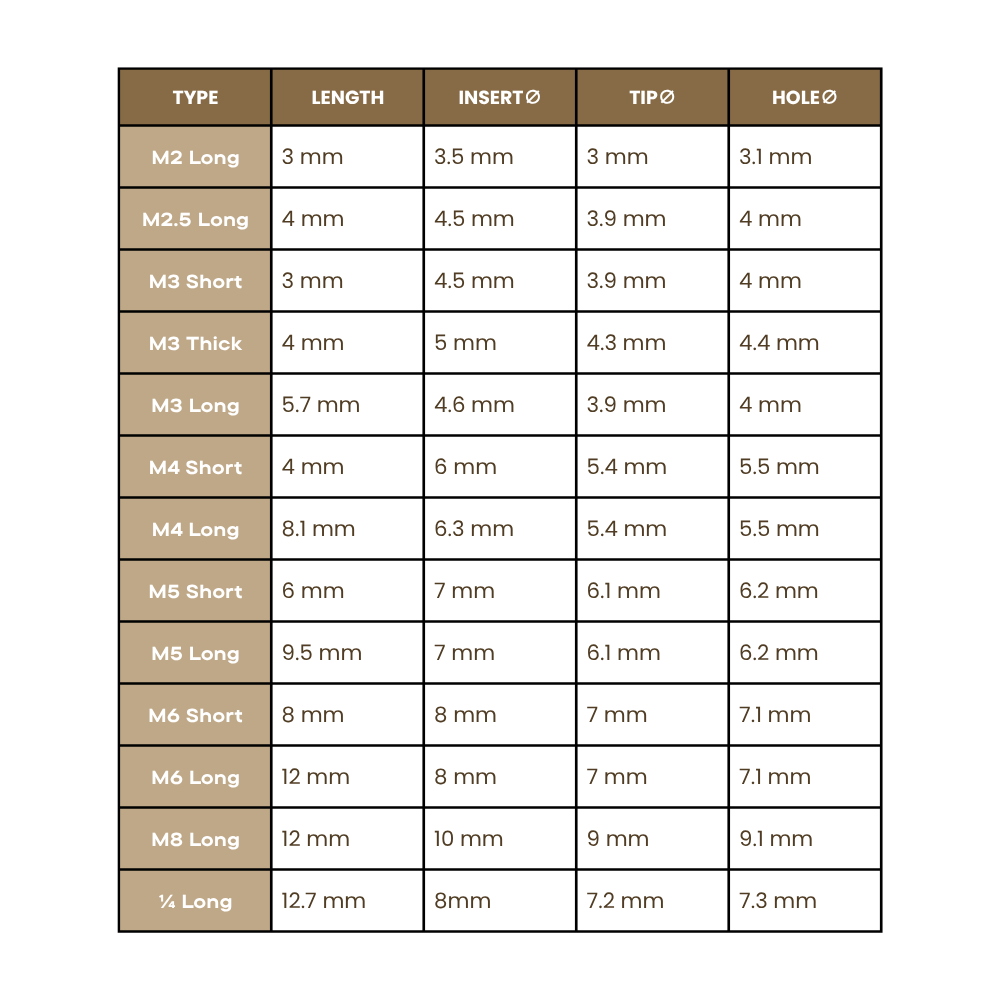

Threaded Inserts Technical Specifications

Threaded Inserts are knurled brass inserts that provide an efficient and secure way to affix an item to another. With its heat-set construction, the insert maintains a secure and reliable hold for arts and crafts, furniture, and other 3D printed objects.

For easy installation set the Soldering Iron to the filament printing temperature +10° Celsius.

Small Parts. Serious Strength.

Made from high-quality brass with precision knurling, OzFDM’s threaded inserts deliver outstanding grip, heat transfer, and long-term stability across both plastic and resin components.

Designed to pair perfectly with our range of PLA+, PETG, and other 3D-printing materials, they provide reliable fastening for any project.

Whether you’re assembling enclosures, upgrading mechanical parts, or finishing functional prototypes, OzFDM’s inserts ensure your prints stay strong, secure, and professionally finished every time.

Built to Bond, Made to Last

Compatible, Reliable, and Ready to Perform

OzFDM’s brass inserts work seamlessly with a wide range of 3D-printing materials, including PLA, PLA+, PETG, ABS, and Nylon.

Their precise knurled geometry and smooth surface make installation simple and alignment effortless. Designed for both high- and low-temperature plastics, they deliver a professional-grade fastening solution that improves the strength, appearance, and durability of every print, from prototypes to production-ready parts.

Built for Strength and Longevity

Exceptional Holding Power

Every detail of OzFDM’s Knurled Brass Threaded Heat Inserts is engineered for strength, consistency, and performance. Each insert features a precisely cut knurled exterior designed to lock tightly into plastic once heat-set, forming a permanent mechanical bond that won’t loosen or shift over time. The deep, diamond-patterned ridges bite securely into the surrounding material, preventing pull-out, rotation, or slippage under pressure.

This mechanical grip makes a real difference in parts that experience frequent stress or repeated assembly. Whether you’re creating a hinged enclosure, mounting a bracket, or building a mechanical fixture, the inserts hold firm through countless fastening cycles. The corrosion-resistant brass construction further ensures that each thread maintains its integrity and strength even after extensive use, making them ideal for both prototyping and long-term production applications.

Perfect Fit for Every Project

OzFDM offers a complete range of insert sizes, covering everything from M2 to M8 threads (and 1/4”), giving makers full flexibility across all project types. Whether you’re reinforcing small precision components or strengthening larger mechanical joints, there’s an option perfectly matched to your design. Each insert is produced to exact tolerances and rigorously tested to guarantee accuracy, consistency, and an easy fit straight out of the box.

The result is a dependable connection that feels professional and repeatable, without the frustration of trial and error. No matter your application or material, OzFDM’s inserts help turn simple prints into robust, ready-to-use components.

Professional Results, Simple Installation

Installing heat-set inserts is quick, efficient, and accessible for any maker. Heat your soldering iron to the recommended temperature and gently press the insert into a slightly undersized hole. As the brass heats, it transfers that energy evenly through the knurled surface, softening the plastic just enough to allow a perfect, controlled embed.

Once cooled, the plastic re-solidifies around the insert, locking it firmly in place. The final result is a clean, flush, and professional-looking thread that’s built for precision and durability. From simple prototypes to finished products, OzFDM inserts make it easy to achieve results that look as refined as they perform.