1.75 mm PPA-CF Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

OzFDM PPA-CF Filament

OzFDM’s PPA-CF brings together a high performance PPA base with finely milled carbon fibre to deliver serious strength, stiffness, and heat resistance, specifically designed for users who need engineering grade parts. PPA-CF offers excellent dimensional stability, low creep, and dependable layer adhesion so prints stay accurate even under sustained mechanical load. The reinforced matrix reduces warping and shrinkage compared with standard nylons, making it easier to achieve clean, predictable results with sharper edges, tighter tolerances, and less print variation, even on demanding structural parts.

A reliable and consistently performing filament, developed for functional components and real world assemblies, PPA-CF stands up to elevated temperatures, repeated stress, harsh environments, it resists many oils and chemicals, holds threads well, and maintains rigidity where other materials may soften or deform. Whether you are building brackets, drone or automotive parts, or production ready fixtures, PPA-CF delivers a refined technical finish and performance that earns its place in demanding applications, producing parts that look sharp, feel solid, and continue to perform long after installation.

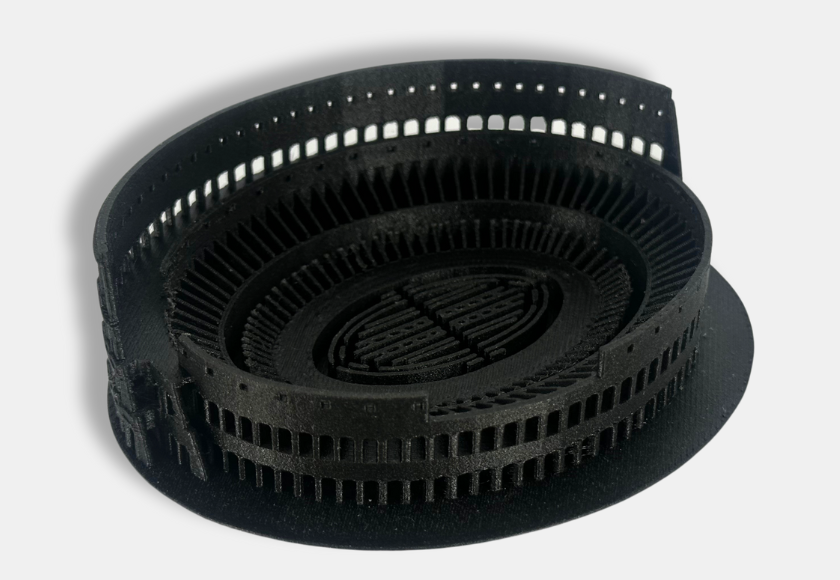

All 3 models displayed are produced with our OzFDM PPA-CF, in the Black Carbon Fibre shade, 3D printed by Global3D

The Eiffel Tower, the Colosseum and a Benchy Boat

When strength is the priority, one shade is all you need.

Carbon Fibre Black - PPA-CF

PPA-CF is available in a single, purpose built Carbon Fibre Black shade that reflects its engineering focus. The dark, slightly textured surface hides wear, fingerprints, and minor artefacts while emphasising the material’s structural character. This carbon rich finish masks layer lines, photographs cleanly, and pairs well with both vibrant and industrial colour palettes used elsewhere in your build.

Choose Carbon Fibre Black when you want parts that look serious, technical, and ready for work straight from the print bed.

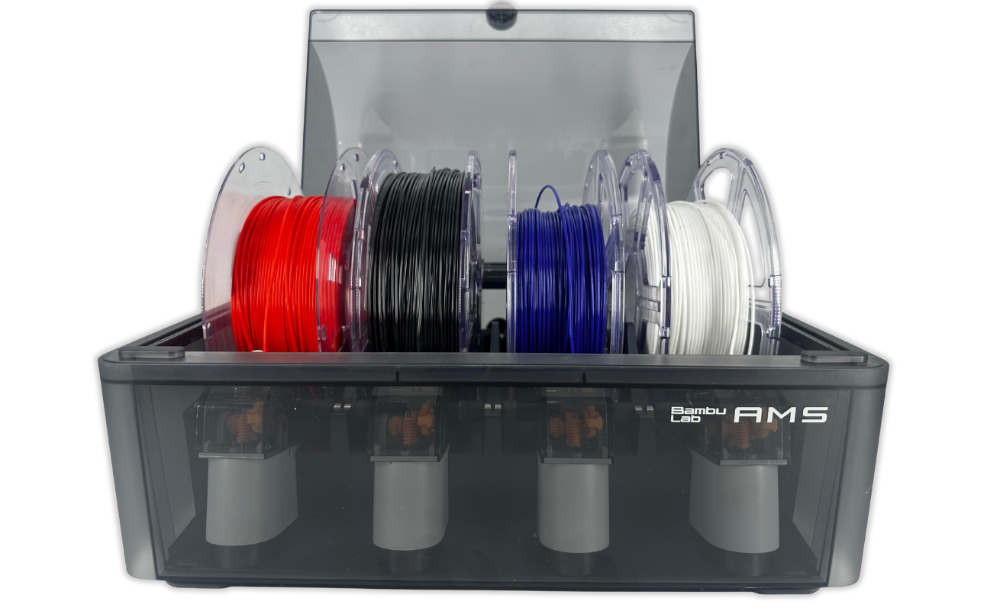

AMS Compatibility - Careful and Controlled

PPA-CF can be used with AMS systems in suitable conditions, but it rewards a considered setup. The material is sensitive to moisture and prints at elevated temperatures, so we recommend drying the filament thoroughly and limiting AMS storage time to shorter runs rather than long term loading.

When handled properly, AMS feeding can offer convenient automatic material changes while maintaining reliable flow. Due to PPA-CF's abrasive nature and high temperature capabilities, it must be used with a hardened nozzle and a printer suitable for its recommended print temperatures to prevent printing problems.

If you prefer to maximise service life of AMS components or frequently run very hot and fast profiles, using an external dry box with direct feed may be the better choice. Select the approach that best matches your workflow, and PPA-CF will return strong, precise parts with minimal fuss.

Performance Refined for Real World Printing

Built for High Demand Projects

PPA-CF is engineered for critical components where failure is not an option, its excellent tensile strength, stiffness, and fatigue resistance for brackets, arms, housings, and fixtures that experience real, everyday load.

It features significantly lower moisture absorption than standard nylon, maintaining dimensional stability while delivering impressive wear and creep resistance for parts exposed to friction and long term stress.

The carbon fibre reinforcement supports the filament under bending and torsion, helping parts retain form and accuracy through repeated use.

Together, these properties give you a filament that maintains structural integrity and dependable performance even in demanding environments.

Stable, Accurate and Consistent

The semi aromatic PPA base gives PPA-CF a naturally stable foundation, helping it hold its shape far more reliably than many traditional nylon blends. This unique feature sets PPA-CF apart from other nylon blends in terms of structural integrity and durability.

With reduced shrinkage and noticeably lower warping, prints come off the bed with cleaner lines, truer dimensions, and reliably formed openings.

This stability allows interference fits, bearing seats, and threaded inserts to align exactly as intended, minimising post processing and improving overall part accuracy.

By delivering predictable results across both simple and complex geometries, PPA-CF lets you design with confidence and push tolerances further without compromising reliability.

Ready for Heat, Stress and Motion

With elevated heat resistance and strong interlayer bonding, PPA-CF is comfortable in environments where PETG or PLA based materials may soften or creep. It stays firm in warm enclosures, around motors, and in fixtures that see repeated motion or clamping pressure.

PPA-CF is a reliable choice for those looking for a filament that can withstand high temperatures and maintain its structural integrity in demanding environments.

For makers and engineers who need a filament that can move from prototype to production ready parts, PPA-CF offers a confident blend of strength, stability, and long term reliability.

PPA-CF Technical Specifications

Each spool of OzFDM’s premium PPA-CF filament is securely vacuum sealed with a moisture absorbing desiccant to maintain optimal print quality right up to that special moment you open the box.

Every package includes recommended printing and drying settings, ensuring you achieve smooth, consistent results right from your first layer.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.05mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

100°C for a minimum of 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

These details outline how PPA-CF behaves during the printing process, helping you dial in stable and predictable results. Understanding its flow, shrinkage, and temperature needs ensures each part prints cleanly and consistently.

For best results, follow the recommended print parameters provided below to achieve reliable, high-quality prints every time.

Nozzle temperature

260°C - 290°C

Bed temperature

70°C - 100°C

Printing speed

40mm/s - 150mm/s

Support material

The mechanical specifications show how PPA-CF performs once printed, including its strength, stiffness, and resistance to repeated stress. These values help you choose confident applications where durability and load bearing performance matter.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

230~250 Mpa

Elongation at Break

ISO 527

2~3 %

Flexural Modulus

ISO 527

5300~5500 Mpa

Flexural Strength

ISO 178

250~280 Mpa

Impact Strength

ISO 180

30~40 KJ/m²

The physical properties describe the material’s density, structure, and overall behaviour in its solid state. This information supports accurate part modelling and helps you design with reliable dimensional expectations.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.22~1.23 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

3~6 g/10min

Moisture Absorption (23°C/24h)

ISO 62

<0.1 %

The thermodynamic metrics highlight how PPA-CF responds to heat, including its stability, resistance, and working temperature limits. These insights guide you when selecting components that need to hold shape and function in elevated temperature environments.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

220 °C

Continuous Use Temperature

IEC 60216

-