1.75 mm ABS+ Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

OzFDM ABS+ Filament

OzFDM's 1.75mm ABS+ filament is designed for makers and engineers who need strength, reliability, and finish quality that feels professional straight off the printer. Building on the foundation of traditional ABS, the enhanced “plus/+” formulation brings improved dimensional stability, stronger interlayer bonding, and lower shrinkage, allowing you to print large or complex parts with greater confidence and fewer warping issues. It holds its shape where many other filaments would twist or lift, producing clean edges and crisp surfaces that stay true to your original design.

The satin finish has a naturally refined texture that sands easily and takes paint beautifully, making it ideal for projects that need both durability and presentation value. Whether you are creating functional prototypes, mechanical brackets, automotive fittings, or sturdy enclosures that live in demanding environments, ABS+ provides a balanced combination of mechanical toughness and print predictability. It performs where PLA reaches its limits and bridges the gap between accessible printability and professional grade final application strength, giving you the freedom to push design boundaries.

Colourful Filament for Every Occasion

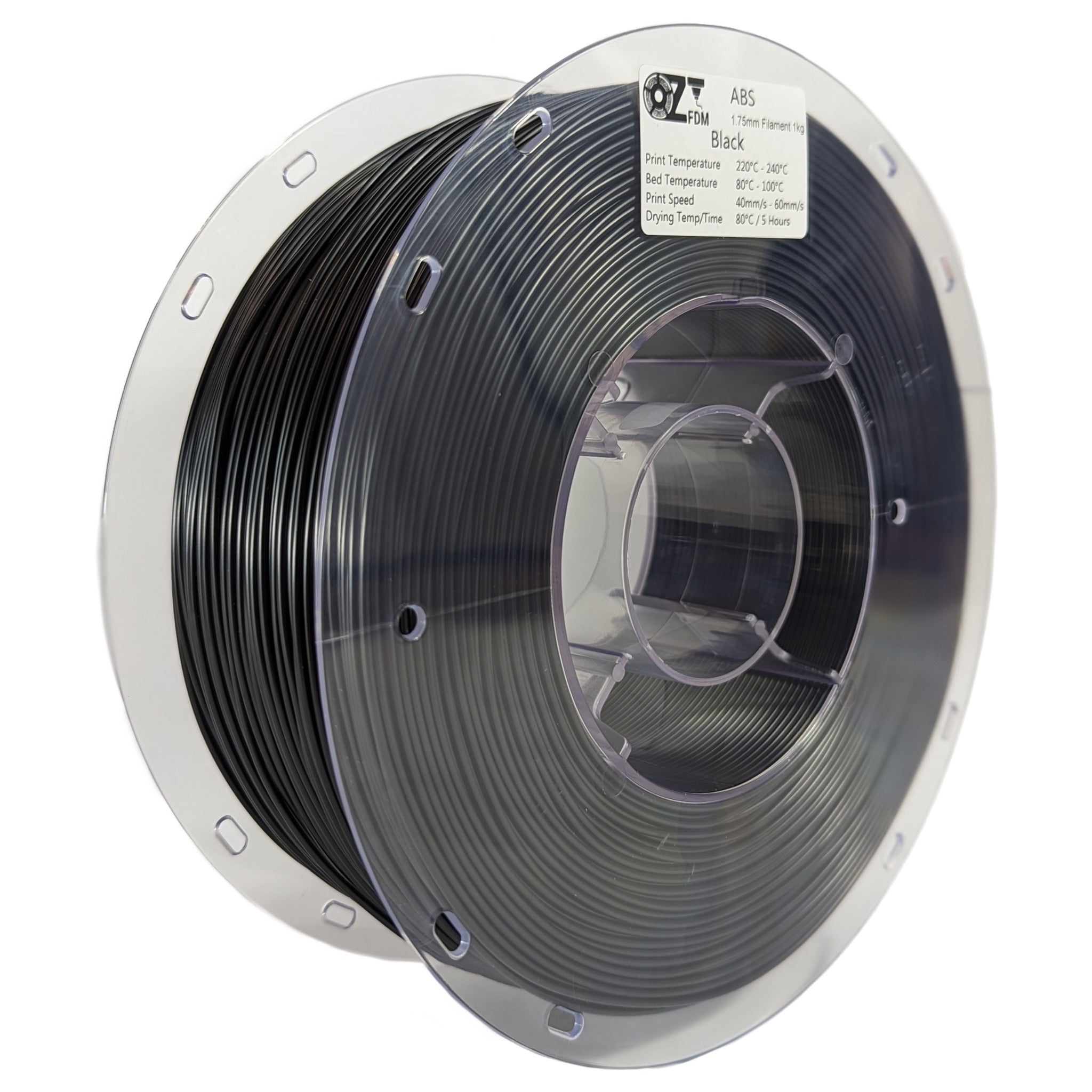

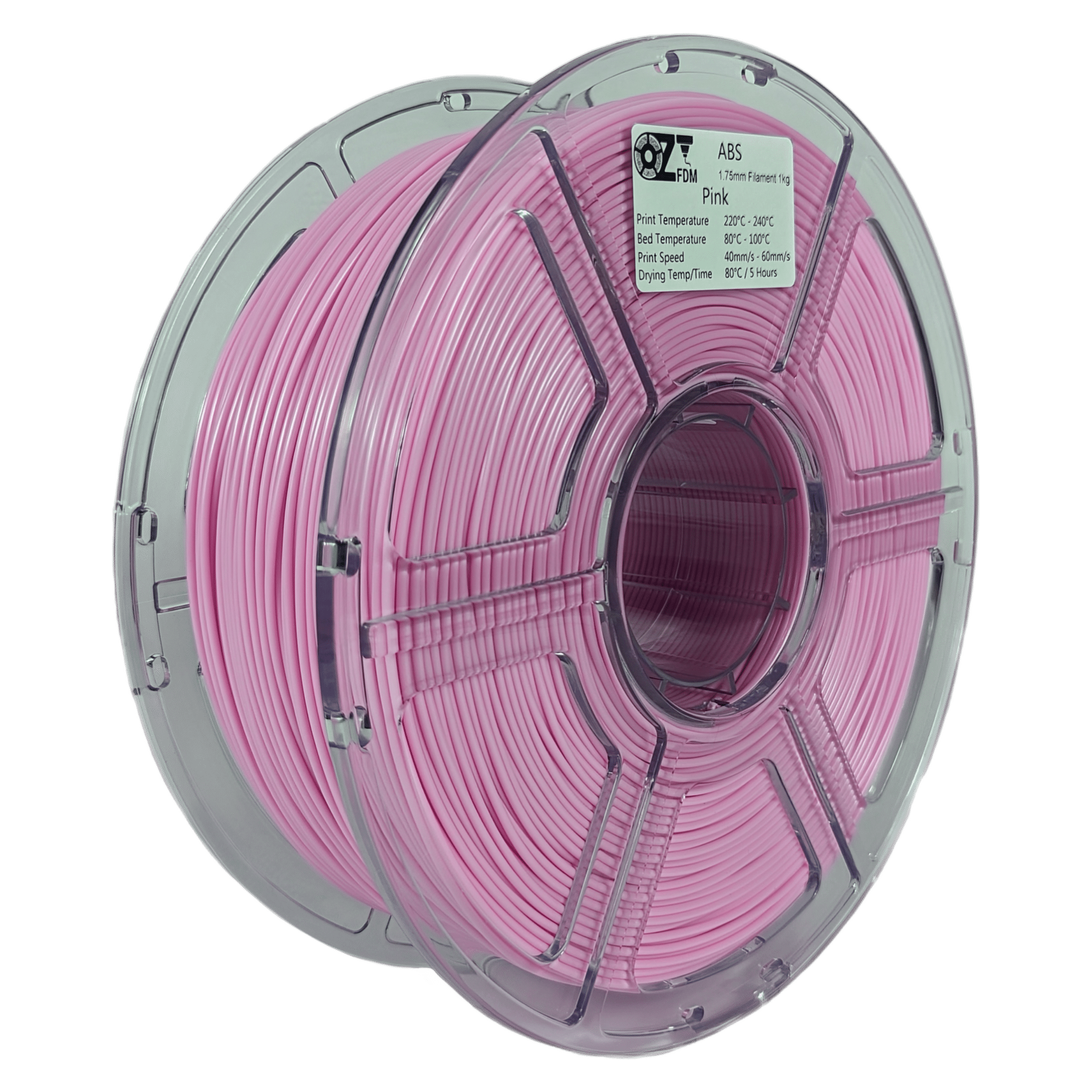

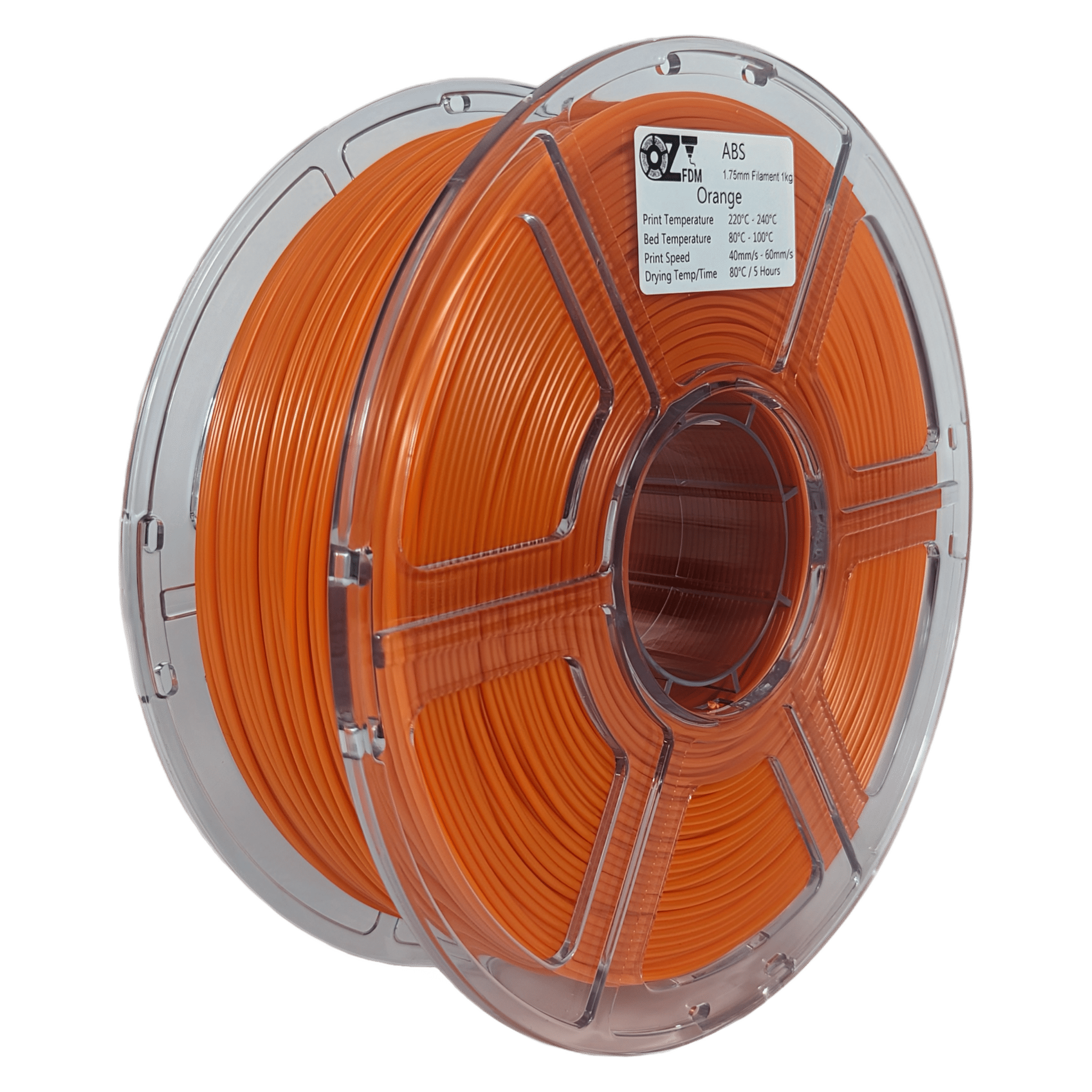

Vibrant Shades to Suit Every Scheme - ABS+ Colour Range

From subtle tones to bold our ABS+ range spans 16 versatile shades designed to match the purpose of your build. Each colour carries the same smooth satin finish and consistent extrusion quality, ensuring your parts print as cleanly as they look.

Whether you are printing functional prototypes, polished display models, or custom assemblies that need to blend or stand out, there is a tone to fit every style. The colour pigments are carefully balanced to maintain even flow, heat stability, and a uniform surface across the full spectrum, giving you the confidence to mix practicality with design expression in every print.

Disclaimer: All colour representations have been selected using the Nix Mini 3 Colour Sensor to ensure accuracy and consistency across our filament range. While every effort has been made to provide precise HEX code values, slight variations may occur due to differences in lighting conditions, display settings, and manufacturing batches. For the most accurate results, always refer to physical samples or printed models under your typical lighting environment.

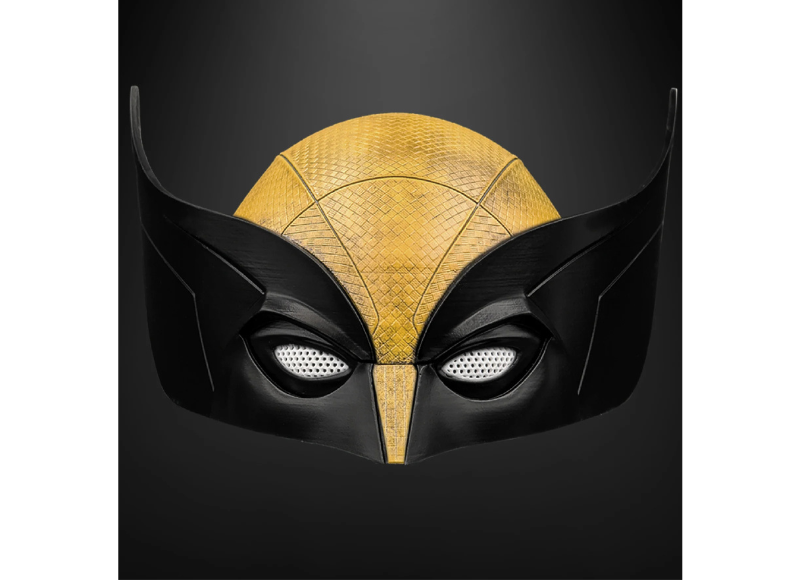

OzFDM Maker Community Standout

Props & Pixels - Meets ABS+

Meet Props & Pixels and founder James Plumb, where imaginative fandom meets precision making. James turns high impact design into premium replicas, utilising our OzFDM filament, especially ABS+ to bring show worthy armour, props and fixtures to life with more than just visual fidelity. His builds exhibit mechanical strength, durable layering and a surface finish that stands up to display, cosplay or everyday use.

By choosing ABS+ for its stable interlayer adhesion and refined satin texture, James ensures that even the most dynamic designs hold form, handle handling and deliver clean lines that photograph beautifully. We’re honoured to support his creative journey and excited to see how his work inspires the maker community, thank you Props & Pixels.

Grimdark: UM LT Helmet - OzFDM ABS+

Gladiator: Maximus Shield - Prop or Cosplay - OzFDM ABS+

Marvel: The Wolverine Cowl - Prop or Replica - OzFDM ABS+

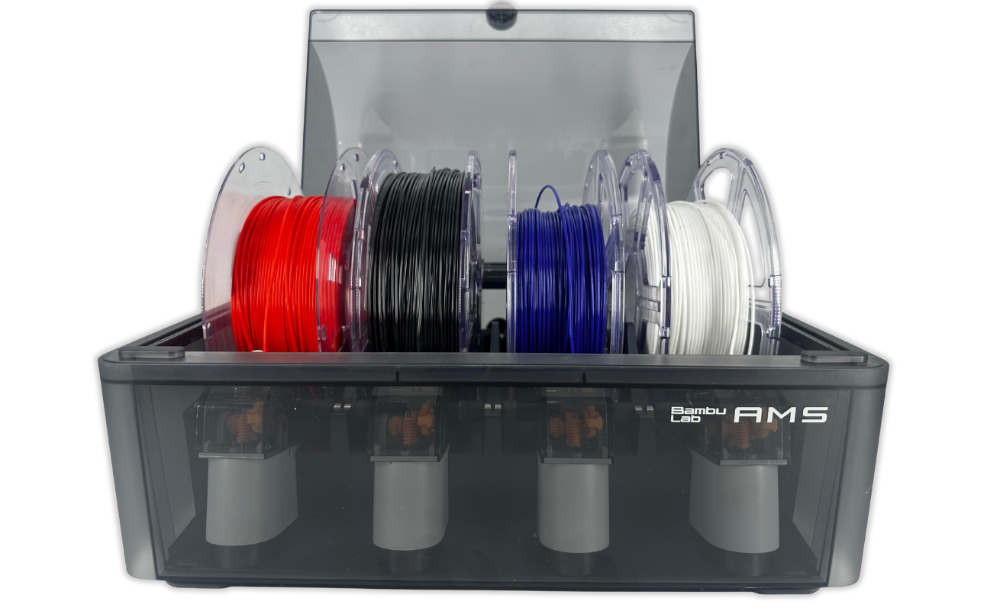

Smart Spooling, Consistent Results

AMS-Compatibility and Spool Guidence

If you use an AMS style feeder, ABS+ is compatible from a feed standpoint, but the material still benefits from an enclosed printer to control draft and heat loss, ensuring that you keep the spool dry and guarantee low friction unwinding.

If your stock spool shape is not ideal for your feeder, load the filament onto an AMS compatible reusable spool to maintain smooth flow.

For large prints, place the AMS and spool away from heat sources to prevent softening, and keep part cooling low to protect layer strength.

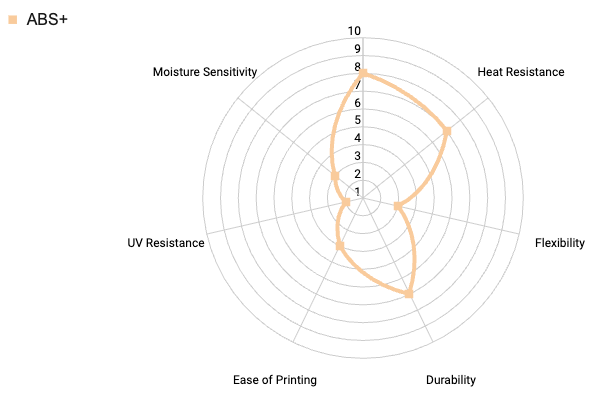

Inside the ABS+ Profile

- Showcases ABS+’s strongest traits, including its impressive heat resistance, robust strength, and enhanced durability, making it a dependable choice for parts that need to withstand real world stress and higher operating temperatures.

- Highlights areas where ABS+ requires more care, such as its sensitivity to moisture, moderate flexibility, and the need for controlled printing conditions to achieve optimal results.

- Offers a clear overview of why ABS+ remains a go to material for functional components, prototypes, and engineering style prints delivering a balance of toughness, stability, and professional grade performance when dialled in correctly.

Refined Strength in Every Layer

Why ABS+ Is More Than Just Another Filament

Built for Everday Engineering

ABS+ is the material you reach for when parts need to look professional and work without fuss. It prints with a steady flow and a satin surface that hides layer transitions, so brackets and covers do not scream “prototype.”

The lower warp tendency compared with standard ABS means you can push to larger footprints when your bed is clean, level, and warm.

Add a brim for wide plates or thin walls, and you will see edges stay planted while the part builds. When a model calls for inserts, ABS+ grips brass knurls well and holds threads with confidence.

Consistent Results in Real Conditions

Workshops, garages, and vehicles are not gentle on plastics, and ABS+ manages heat better than PLA and keeps shape where many entry level materials drift.

That stability lets you design tighter press fits, align holes across tall features, and rely on fixtures that live near tools and lighting. If your printer has an enclosure, you will enjoy balanced layers and fewer surface marks from drafts.

Dry filament makes all the difference for clarity and finish, so give spools a short bake and store them sealed between jobs.

Finishes that Elevate your Builds

A refined finish can turn a good print into a product ready part, ABS+ sands quickly, accepts primer in minutes, and paints to a uniform tone with little effort.

Solvent bonding enables clean, hidden seams and durable multi part shells. If you need a near molded appearance for a hero photo, a careful vapor polish can level the micro texture and bring a soft sheen to the surface.

From first print to final assembly, ABS+ supports the steps that make your work feel considered and complete.

OzFDM's ABS+ Technical Specifications

ABS+ is an enhanced formulation of the classic engineering grade material trusted across countless industries. It balances strength, surface quality, and consistent performance, giving you a filament that behaves predictably print after print. The improved stability makes it suitable for both professional and hobbyist applications, offering a reliable way to produce parts that look refined yet stand up to practical use. Whether used for structural components, replacement parts, or polished display models, ABS+ delivers a clean, durable finish that feels purposeful and engineered.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.03mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

80°C for a minimum of 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

ABS+ prints smoothly when handled with care and attention to environmental control. It provides a steady extrusion flow, reliable layer bonding, and consistent surface texture, making it easy to achieve crisp, professional results. Once dialled in, the material rewards precision with clean edges, balanced sheen, and stable, repeatable outcomes across a wide range of prints.

For best results, follow the recommended print parameters provided below to achieve reliable, high-quality prints every time.

Nozzle temperature

220°C - 240°C

Bed temperature

80°C - 110°C

Printing speed

40mm/s - 60mm/s

Support material

Strong, resilient, and built for practical function, ABS+ offers the durability needed for both prototype and end use parts. Its balanced rigidity and impact resistance make it suitable for models that experience regular handling, assembly, or load. The improved interlayer adhesion supports confident use in structural or mechanically stressed designs.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

33~37 Mpa

Elongation at Break

ISO 527

9~15 %

Flexural Modulus

ISO 527

1500~1650 Mpa

Flexural Strength

ISO 178

65~67 Mpa

Impact Strength

ISO 180

12~13.5 KJ/m²

With a satin surface that conceals layer lines, ABS+ produces refined, visually appealing results that feel professional in hand. It can be easily post processed for cosmetic enhancement or bonded for multi part assemblies. Dimensional accuracy and consistent texture make it a dependable choice for prints where visual quality and functional precision matter equally.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.08~1.1 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

2~5 g/10min

Moisture Absorption (23°C/24h)

ISO 62

1 %

ABS+ remains stable when exposed to warmth and mechanical use over time. It holds its form where more basic materials may soften or distort, retaining the accuracy of key details and fitment. This heat resilience allows prints to perform reliably in both display and functional settings without loss of structural integrity.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

85 °C

Continuous Use Temperature

IEC 60216

-