1.75 mm TPU95A Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

OzFDM TPU95A Filament

OzFDM's 1.75mm TPU95A filament is a versatile thermoplastic polyurethane engineered to deliver flexible performance without the usual challenges of soft materials. With a Shore hardness of 95A, it strikes the perfect balance between elasticity and control, making it firm enough to hold its shape under load, yet soft enough to absorb shock, vibration, and repeated bending without cracking. This strong yet adaptable filament is ideal for crafting functional components such as phone cases, protective casings, gaskets, hinges, seals, and even creative pieces like flexible prototypes or textured design models.

Crafted for reliable extrusion, TPU95A glides effortlessly through standard nozzles and resists clogging or deformation in the extruder, even at moderate printing speeds. It offers excellent layer adhesion, high impact resistance, and remarkable wear durability, enabling printed components to perform consistently in demanding mechanical or environmental conditions. Its chemical resistance also protects against oils, lubricants, and solvents, extending its utility across both consumer and industrial applications, making it a reliable choice for a wide range of project requirements.

Whether you are producing flexible prototypes, shock absorbing components, or final application parts that demand resilience and precision, TPU95A provides the professional reliability of a high performance elastomer with the smooth printability of a standard thermoplastic. Flexible, resilient, and engineered for precision, TPU95A is the go to choice for creators and professionals seeking non compromised quality and dependable results.

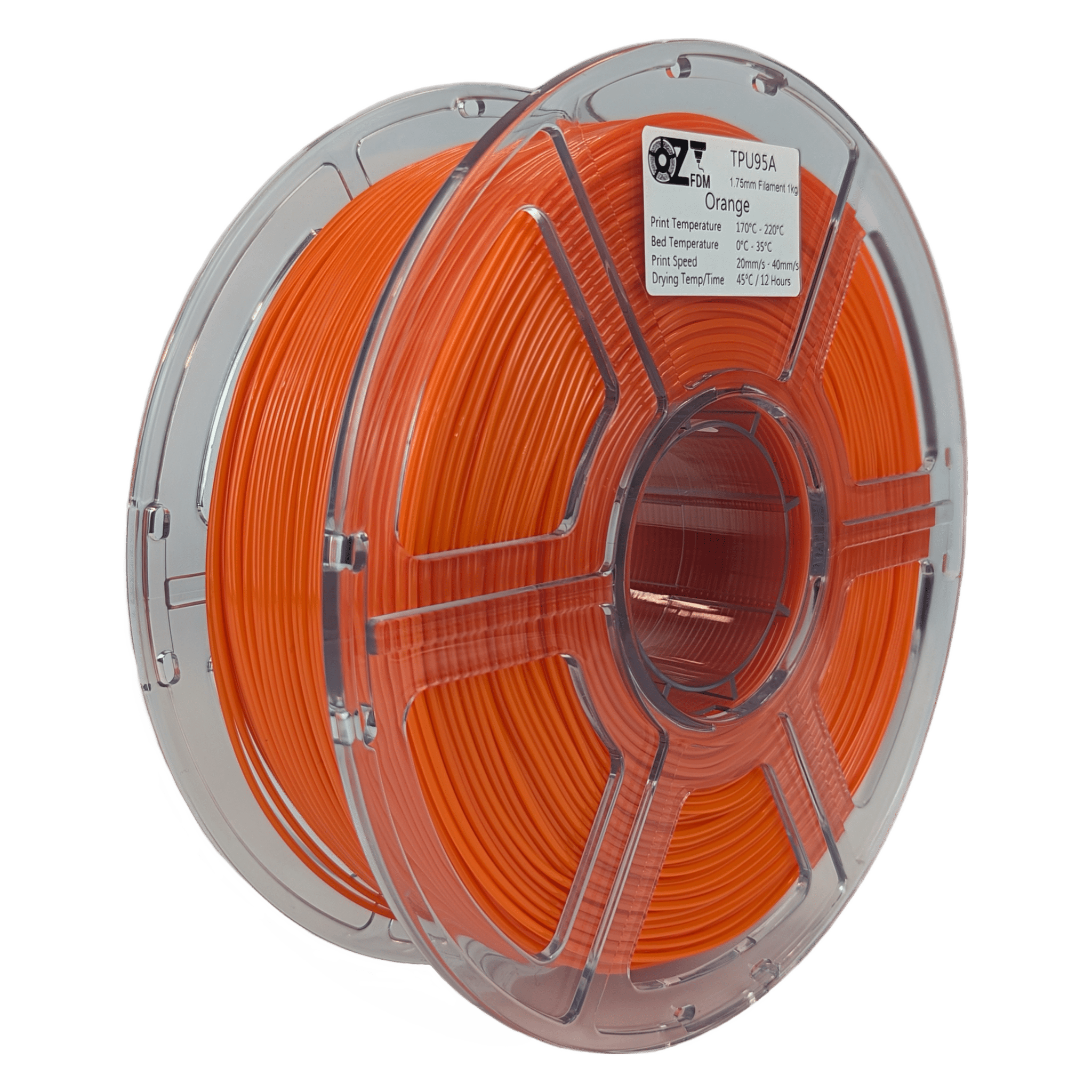

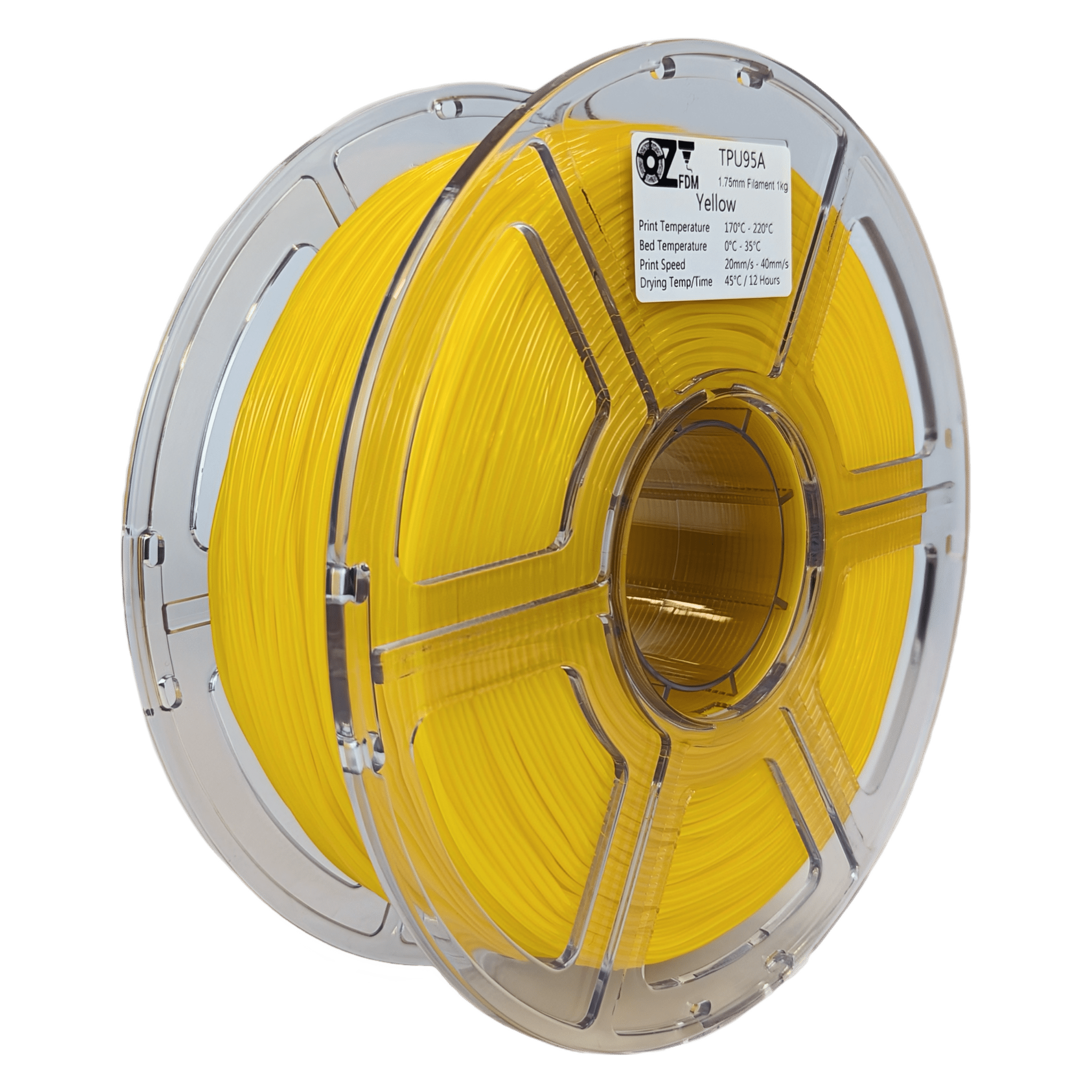

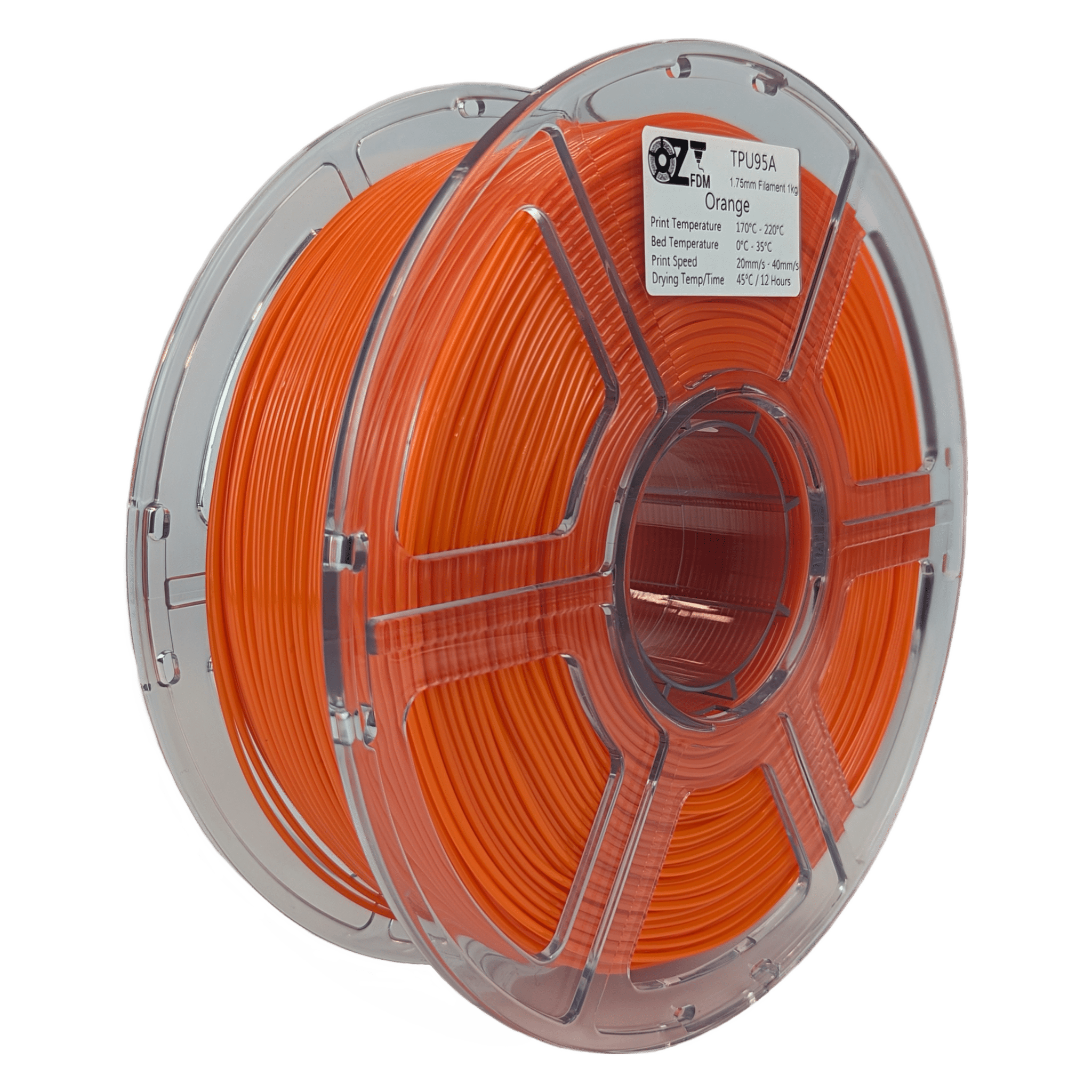

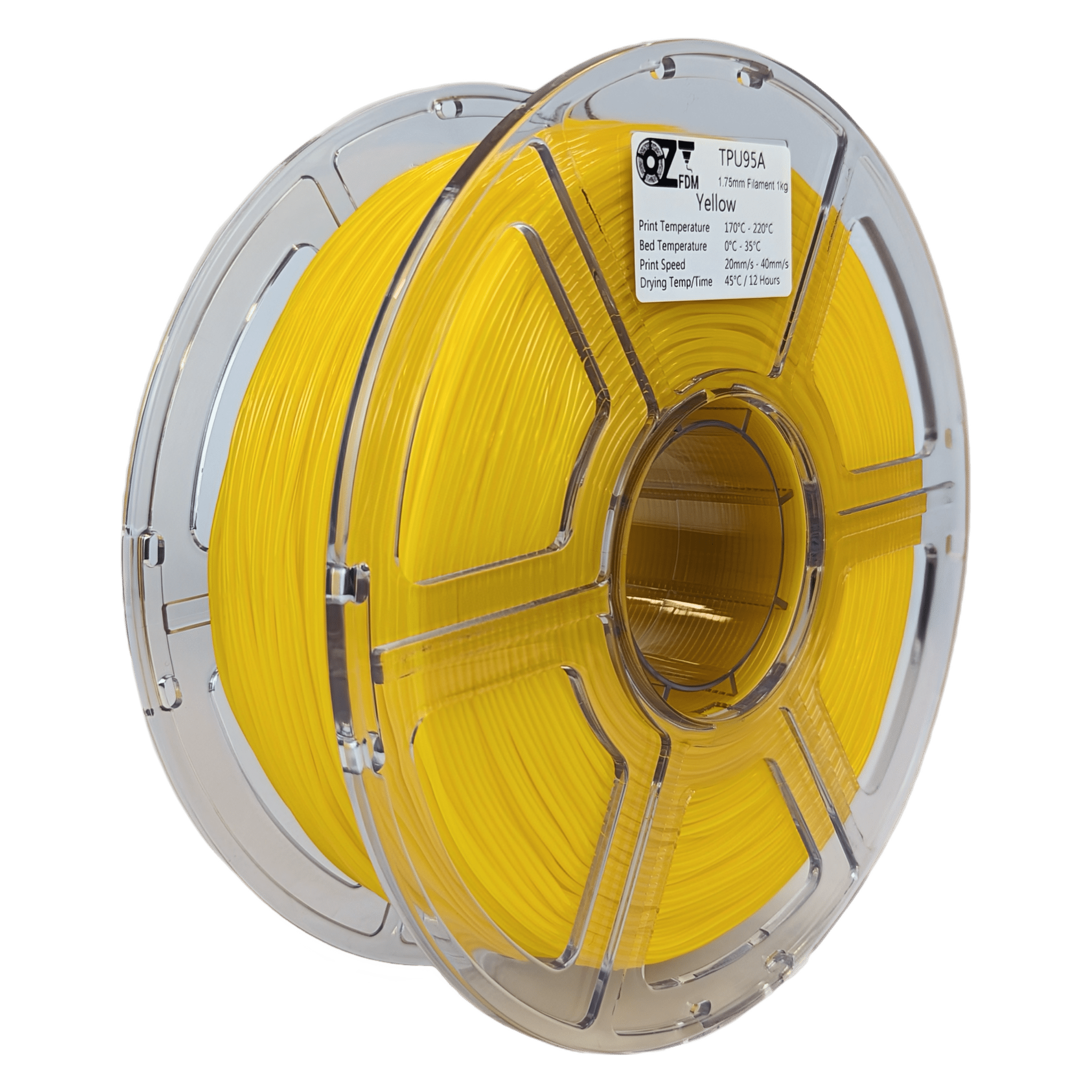

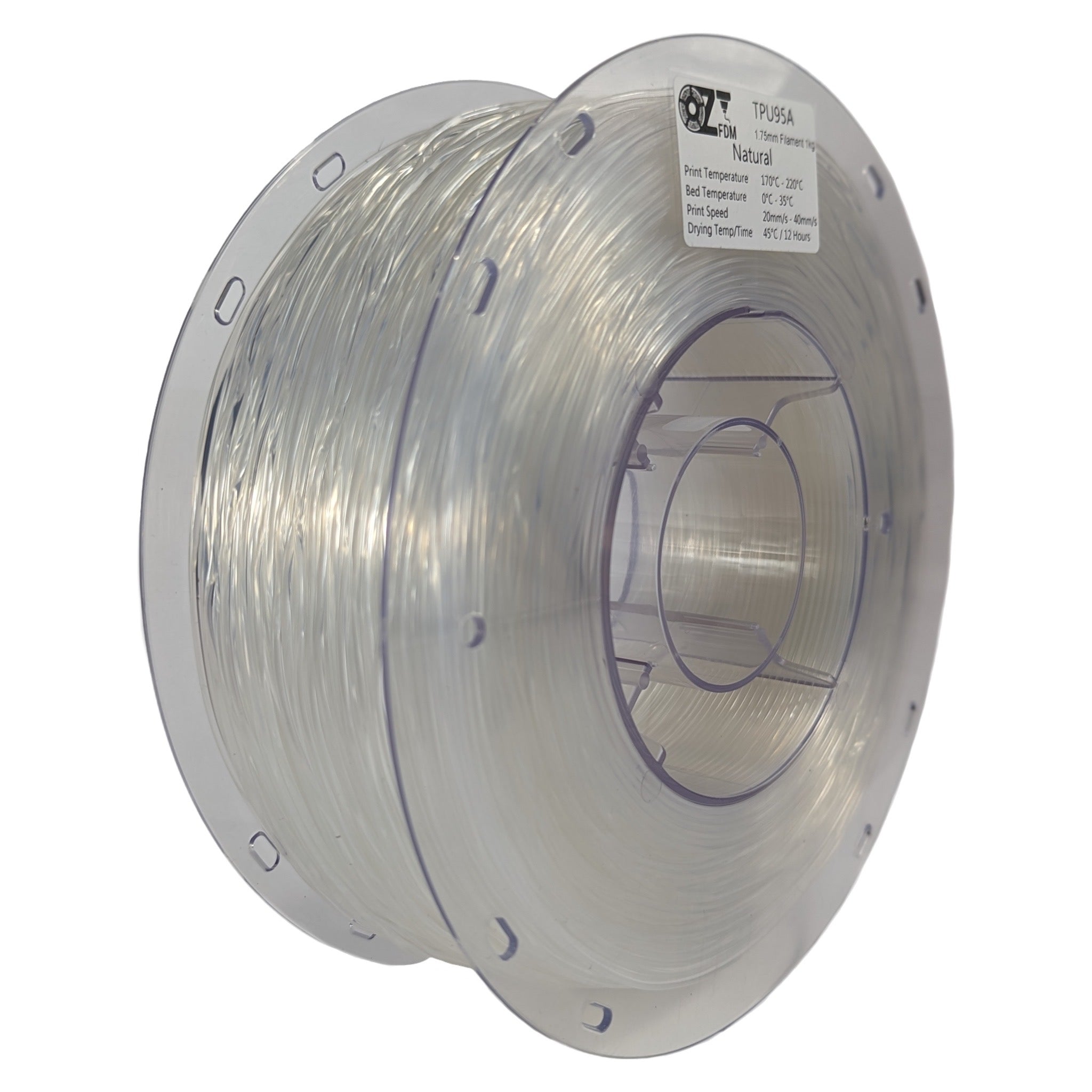

Nine shades, one goal - to make flexibility look as good as it performs.

Dynamic by Design , TPU95A Shades

Available in nine dynamic shades, the TPU95A range offers versatility and expression without compromising performance. From vivid primary hues to pure neutrals and a sleek black, each colour upholds an even pigmentation across the canvas, ensuring a dependable, seamless, and uniform outcome on all your artworks, without fail.

The vibrant hues will bring life and energy to any room, creating a stunning visual impact that is sure to impress. Whether you are printing flexible parts for functional use or creative pieces that need both colour and resilience, the TPU95A range ensures every print looks as good as it performs.

Disclaimer: All colour representations have been selected using the Nix Mini 3 Colour Sensor to ensure accuracy and consistency across our filament range. While every effort has been made to provide precise HEX code values, slight variations may occur due to differences in lighting conditions, display settings, and manufacturing batches. For the most accurate results, always refer to physical samples or printed models under your typical lighting environment.

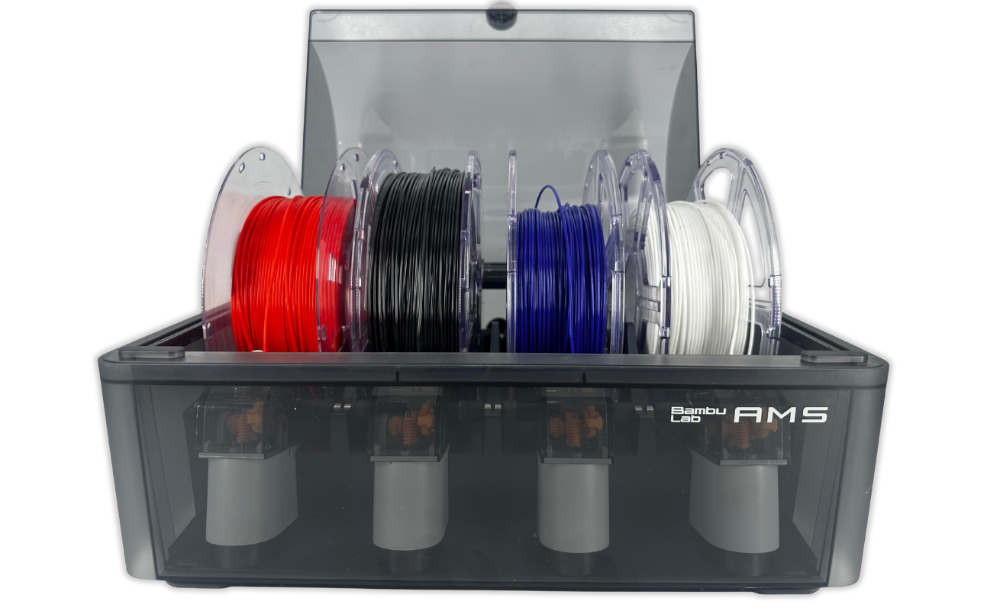

Flexible Material, Manual Loading Recommended

Flexibility Meets Control, AMS Performance Notes

Due to its flexible nature, TPU95A is not fully compatible with AMS or similar multi material systems such as the Bambu Lab AMS. The material’s soft, elastic composition can cause it to compress or buckle within the AMS feeding tubes, leading to unreliable extrusion or jams.

While some users have achieved success by manually loading the filament directly into the extruder and using slower retraction settings, automatic AMS feed systems are generally not recommended for TPU materials.

For best results, bypass the AMS and feed TPU95A directly to the print head, ensuring smoother flow, accurate feeding, and consistent print quality.

Flexibility Meets Control, AMS Performance Notes

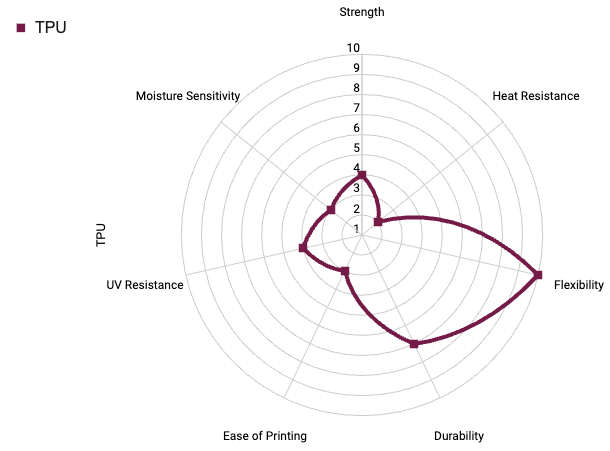

- Captures TPU’s defining advantage, its exceptional flexibility, making it ideal for impact absorbing parts, wearable components, hinges, gaskets, and anything needing movement or bend-ability without breaking.

- Shows where TPU has natural limitations, including low heat resistance, moderate strength, and print challenges that often require slower speeds, tuned retraction, and a stable extrusion setup.

- Provides a clear overview of why TPU is loved for practical, functional applications that rely on resilience and stretch, offering a unique balance of toughness, elasticity, and long term durability when printed correctly.

Designed to Flex, Built to Last

Smooth, Predictable Flexability

OzFDM's TPU95A filament offers an impressively smooth printing experience for a flexible material, where other malleable filaments may fall short. TPU95A maintains consistent extrusion across a wide range of speeds and setups, however, it is recommended yo use a slow print speeds, proper nozzle and the suggested bed temperatures.

Its semi rigid composition provides enough structure for controlled feeding through direct drive systems, helping to minimise stringing, clogging, or deformation during long prints.

Layer adhesion is exceptionally strong, producing seamless walls and uniform surfaces that look clean straight off the bed. Even intricate geometries, overhangs, or thin wall features benefit from its stable flow and low warping tendency.

Whether you are fine tuning prototypes or producing flexible production parts, TPU95A makes flexible printing efficient, predictable, and professional grade.

Built to Absorb and Endure

Behind TPU95A’s flexibility lies impressive mechanical resilience that stands up to real world use. It resists tearing, compression fatigue, and impact stress, allowing printed parts to bend, stretch, and rebound repeatedly without losing form.

The material’s balanced Shore A 95 hardness ensures every component maintains both shape and strength, ideal for parts that need to endure vibration, shock, or continuous motion.

It is perfectly suited for functional components like hinges, couplings, dampers, and wear resistant protective casings that demand a durable blend of flexibility and structure.

TPU95A delivers the toughness of an engineered polymer with the dynamic movement of an elastomer, a true workhorse for applications where ordinary materials would fatigue or fracture.

Resistant, Versatile, and Ready for Real Use

Designed to perform beyond the prototype stage, TPU95A maintains strength and stability in everyday and industrial environments alike.

Its inherent resistance to oils, greases, and many solvents allows it to operate in chemically demanding or high contact settings without degradation.

The satin matte finish conceals layer lines, offering a refined, tactile surface suitable for both functional and consumer facing parts. This combination of chemical toughness, wear resistance, and visual appeal makes it ideal for projects ranging from phone cases and flexible connectors to vibration dampers and footwear components.

Whatever the use, TPU95A consistently delivers professional quality, long term durability, and the dependable flexibility needed to bring practical designs to life.

TPU95A Technical Specifications

Each spool of OzFDM’s premium TPU95A filament is securely vacuum-sealed with a moisture-absorbing desiccant to maintain optimal print quality right up to that special moment you open the box.

Every package includes recommended printing and drying settings, ensuring you achieve smooth, consistent results right from your first layer.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.05mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

70°C for a minimum of 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

TPU95A offers steady extrusion and dependable layer adhesion when printed at moderate speeds. Its semi-rigid structure allows controlled flow through direct drive systems, helping reduce stringing and under extrusion while maintaining clean, accurate detail throughout each print.

For best results, follow the recommended print parameters provided below to achieve reliable, high quality prints every time.

Nozzle temperature

200°C - 240°C (230°C Recommended)

Bed temperature

20°C - 60°C (40°C Recommended)

Printing speed

30mm/s - 150mm/s

(60mm/s Recommended)

Support material

This material combines high elasticity with strong tensile and impact resistance, allowing printed components to bend, stretch, and compress repeatedly without fatigue. Its balance of hardness and resilience makes it suitable for applications that require both flexibility and mechanical durability.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

27~28 Mpa

Elongation at Break

ISO 527

800~1000 %

Flexural Modulus

ISO 527

6~7 Mpa

Flexural Strength

ISO 178

7~9 Mpa

Impact Strength

ISO 180

NB

OzFDM's TPU 95A maintains excellent dimensional stability and a smooth, satin-matte surface finish that feels professional straight off the bed. It resists wear, abrasion, and environmental stress, ensuring parts retain their shape and quality over time.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.2~1.25 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

6~10 g/10min

Moisture Absorption (23°C/24h)

ISO 62

<0.5 %

With strong thermal stability and a high softening point for a flexible material, TPU 95A remains reliable under continuous use and moderate heat exposure. Its resistance to temperature fluctuation ensures printed parts stay consistent in form and function even under demanding conditions.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

95 °C

Continuous Use Temperature

IEC 60216

90 °C