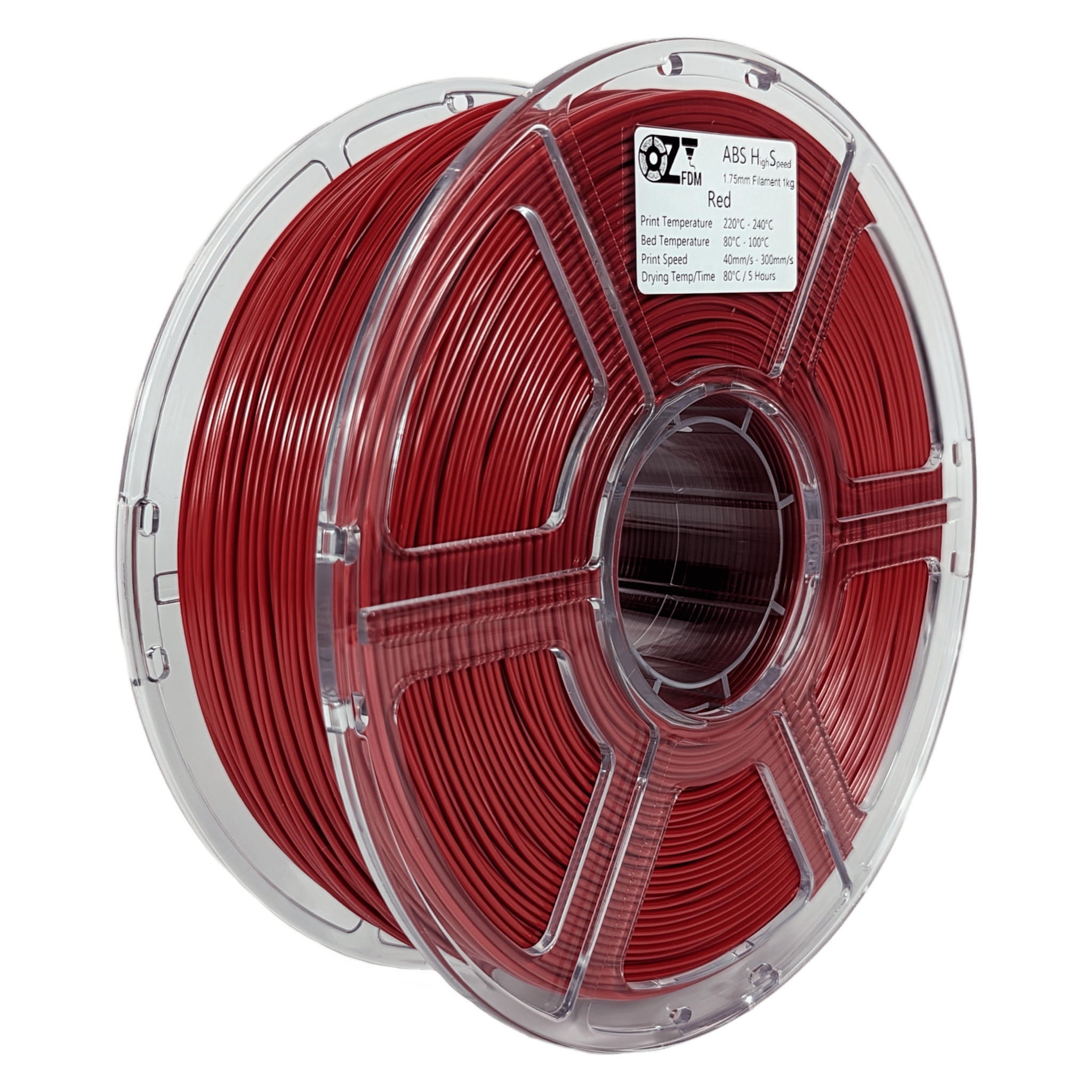

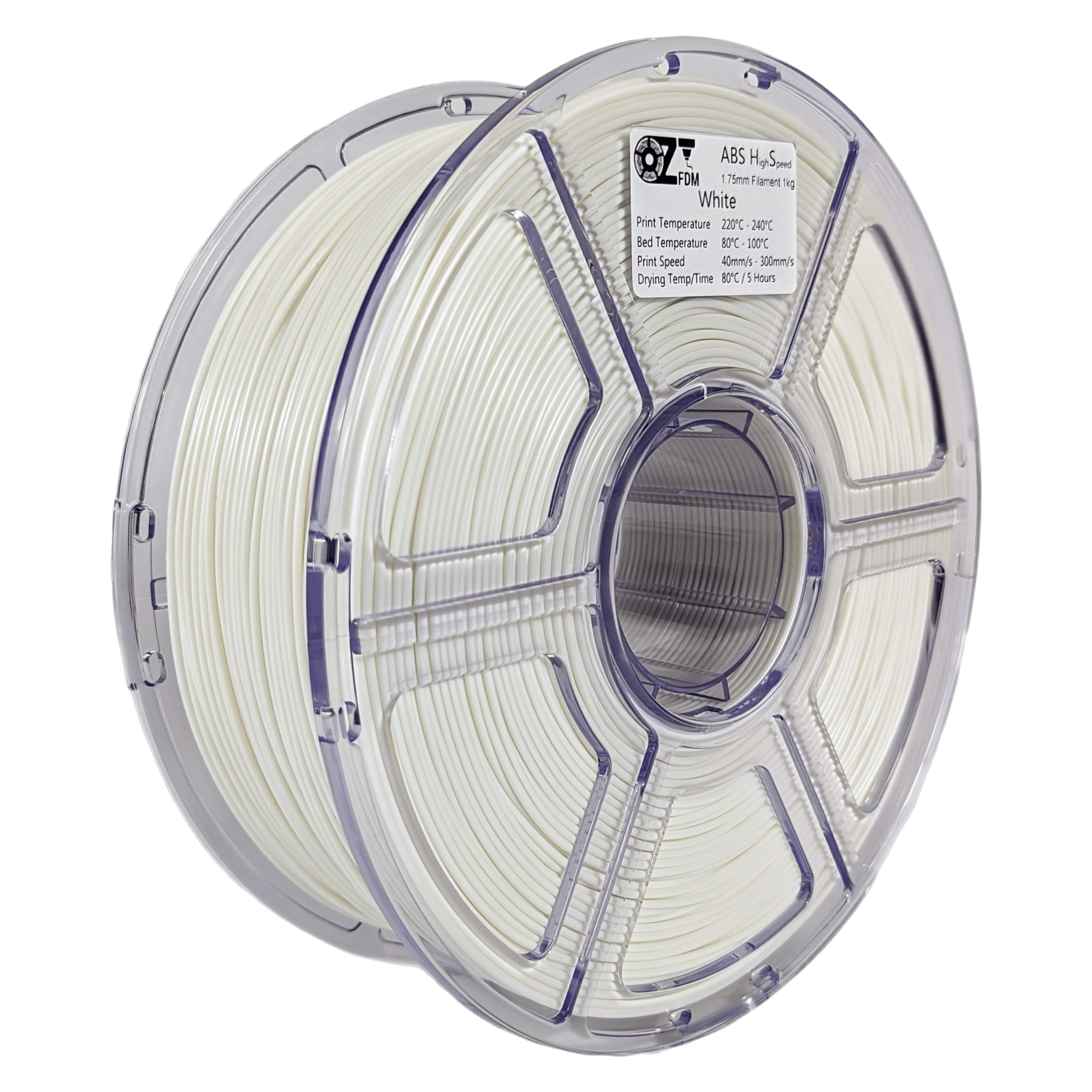

1.75 mm ABS-HS (HighSpeed) Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

OzFDM ABS-HS Filament

ABS-HS takes everything makers love about ABS and enhances it for the modern high speed print environment. Developed with a fine tuned flow index and optimised melt characteristics, it extrudes evenly and predictably at accelerated feed rates, maintaining sharp detail and robust interlayer adhesion even during demanding production runs. Each layer fuses with precision, creating parts that feel dense, stable, and purpose built. This formulation significantly reduces warping, curling, and layer splitting, allowing complex prints to finish cleanly without heavy enclosure requirements.

The result is a filament that thrives in both professional and workshop settings, perfect for users who want to push their printer’s capabilities without compromising reliability. ABS-HS is designed to deliver consistent performance, refined surface quality, and mechanical confidence in every print, whether you’re iterating functional prototypes or producing durable components that need to look as strong as they perform.

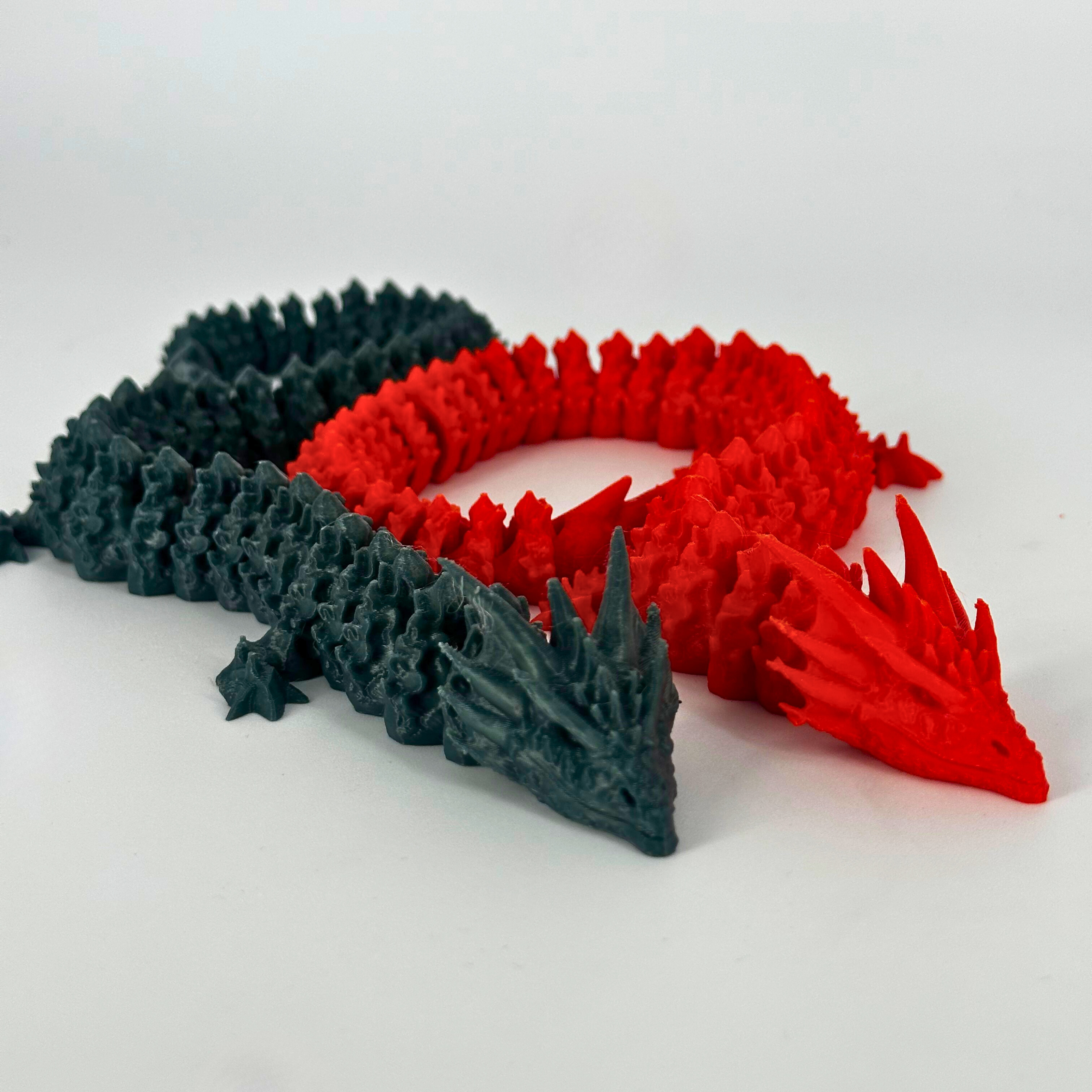

4 Staple Shades For Any Occasion

Create Fast, Print Sharp, ABS-HS Colour Range

Available in four industrial shades, the ABS-HS range combines professional aesthetics with technical function. From sleek neutrals to darker tones suited for functional prototypes, each shade has been formulated for consistent extrusion, minimal sheen variation, and clean matte finish quality.

Disclaimer: All colour representations have been selected using the Nix Mini 3 Colour Sensor to ensure accuracy and consistency across our filament range. While every effort has been made to provide precise HEX code values, slight variations may occur due to differences in lighting conditions, display settings, and manufacturing batches. For the most accurate results, always refer to physical samples or printed models under your typical lighting environment.

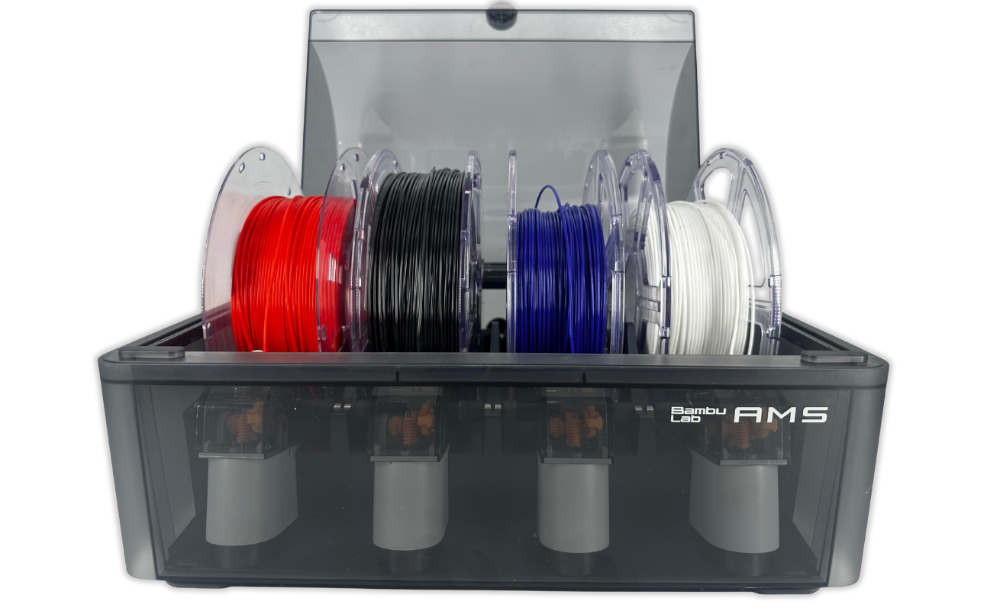

Smart Performance in AMS Systems

ABS-HS performs smoothly within AMS units when configured correctly, making it a reliable choice for makers who want to maintain precision and speed without constant oversight. Its refined flow dynamics and precision wound spools ensure a stable feed path throughout long print sessions, minimising the risk of drag or uneven extrusion even when operating at higher print speeds.

ABS-HS runs at elevated temperatures compared with standard materials, maintaining an enclosed or temperature controlled setup is highly recommended. This helps protect the filament from sudden drafts or ambient temperature shifts that can cause inconsistencies in layer bonding or surface finish.

For users running multi material or continuous production setups, regular monitoring of temperature profiles and calibration settings will ensure optimal flow and consistency between spools.

When dialled in correctly, ABS-HS integrates seamlessly with AMS automation, combining the convenience of multi spool feeding with the durability and warp resistance needed for professional grade prints that deliver both speed and strength.

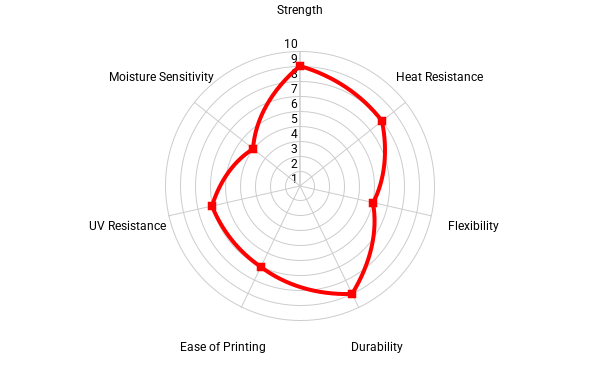

ABS-HS's Personality in a Radar Chart

Understanding ABS-HS at a Glance

The results show ABS-HS as a high-performance filament with exceptional strength, durability, and heat resistance. It offers a noticeable improvement in stability and reduced warping compared to standard ABS, making it more reliable for demanding functional prints. While it benefits from a controlled print environment, it consistently delivers strong, precise, and long-lasting results.

Engineered for Speed and Strength

Fast and Reliable

ABS-HS is engineered for printers that operate at high speed without sacrificing precision. Its refined melt flow ensures smooth, consistent extrusion even during rapid movements, maintaining sharp corners, uniform walls, and stable layer alignment without frequent recalibration.

The advanced formulation promotes consistent filament flow across extended print runs, reducing downtime and improving throughput for demanding production environments.

Whether used for rapid prototyping, batch manufacturing, or time-critical projects, ABS-HS delivers dependable results that keep pace with your workflow.

Experience fast, efficient printing that maintains strength, surface quality, and dimensional accuracy from the first layer to the last.

Tough Enough for Real Use

Every part printed in ABS-HS is designed to handle more than just the test bench, Its impact resistance and rigidity make it ideal for brackets, housings, and jigs that endure constant vibration, tension, or repeated stress without losing form or strength.

The advanced polymer matrix enhances durability and prevents micro-fractures, ensuring parts remain dependable under heavy use or long term wear.

Strong interlayer bonding reinforces structural integrity, giving you the confidence to design components that perform under pressure rather than just look the part.

Combined with consistent thermal stability, ABS-HS maintains its form and function even when exposed to heat, friction, or environmental shifts, a true performer built for practical, real world applications.

Professional Finish Without the Fuss

ABS-HS produces a clean, satin matte surface straight off the bed, giving your prints a refined, professional look without the need for heavy post processing.

Its controlled formulation minimises gloss inconsistencies and hides layer lines effectively, resulting in a smoother, more uniform texture that feels as premium as it looks.

The material’s strong interlayer adhesion also prevents surface defects like cracking or uneven finish, keeping edges crisp and details sharp.

Whether you are printing aesthetic enclosures, precision assemblies, or display ready prototypes, ABS-HS maintains that balance between performance and presentation, delivering prints that are durable, consistent, and visually flawless straight out of the machine.

ABS-HS Technical Specifications

All mechanical, thermal, and physical data for ABS-HS are detailed below. These specifications outline its optimised flow behaviour, high temperature resistance, and dependable structural stability, ensuring each print performs as designed, even under demanding conditions.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.03mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

80°C for a minimum of 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

OzFDM's ABS-HS offers a controlled melt flow and stable extrusion profile, allowing fast, accurate printing without sacrificing dimensional accuracy. Its reduced warping and consistent layer adhesion make it a reliable choice for both enclosed and open setups when calibrated correctly.

For best results, follow the recommended print parameters provided below to achieve reliable, high-quality prints every time.

Nozzle temperature

220°C - 240°C

Bed temperature

80°C - 110°C

Printing speed

40mm/s - 60mm/s

Support material

Engineered for durability, ABS-HS provides high tensile strength, impact resistance, and rigidity across varied printing conditions. The enhanced layer bonding helps maintain integrity in load bearing applications where both stability and longevity matter.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

35~40 Mpa

Elongation at Break

ISO 527

12~17 %

Flexural Modulus

ISO 527

1500~1650 Mpa

Flexural Strength

ISO 178

65~70 Mpa

Impact Strength

ISO 180

7~10.5 KJ/m²

ABS-HS maintains a stable structure and balanced density, producing parts that are dimensionally accurate and resistant to shrinkage during cooling. Its satin matte finish hides minor layer lines and surface variations, giving every print a clean, uniform appearance.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.04~1.06 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

2~4 g/10min

Moisture Absorption (23°C/24h)

ISO 62

1 %

With a high glass transition temperature and strong resistance to thermal deformation, ABS-HS performs reliably under prolonged heat or environmental stress. This temperature stability ensures printed parts remain rigid and functional, even in demanding applications or elevated operating conditions.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

88 °C

Continuous Use Temperature

IEC 60216

-