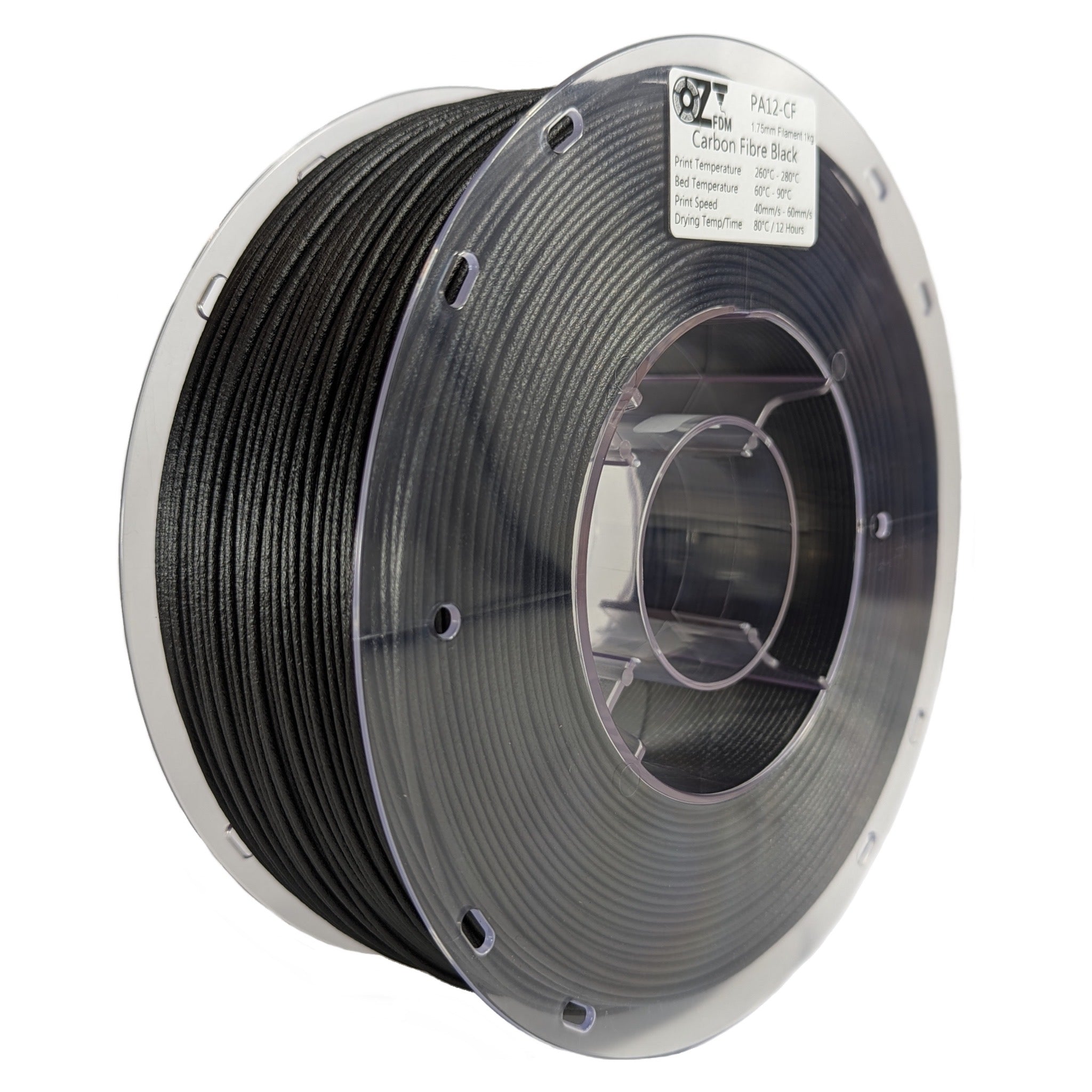

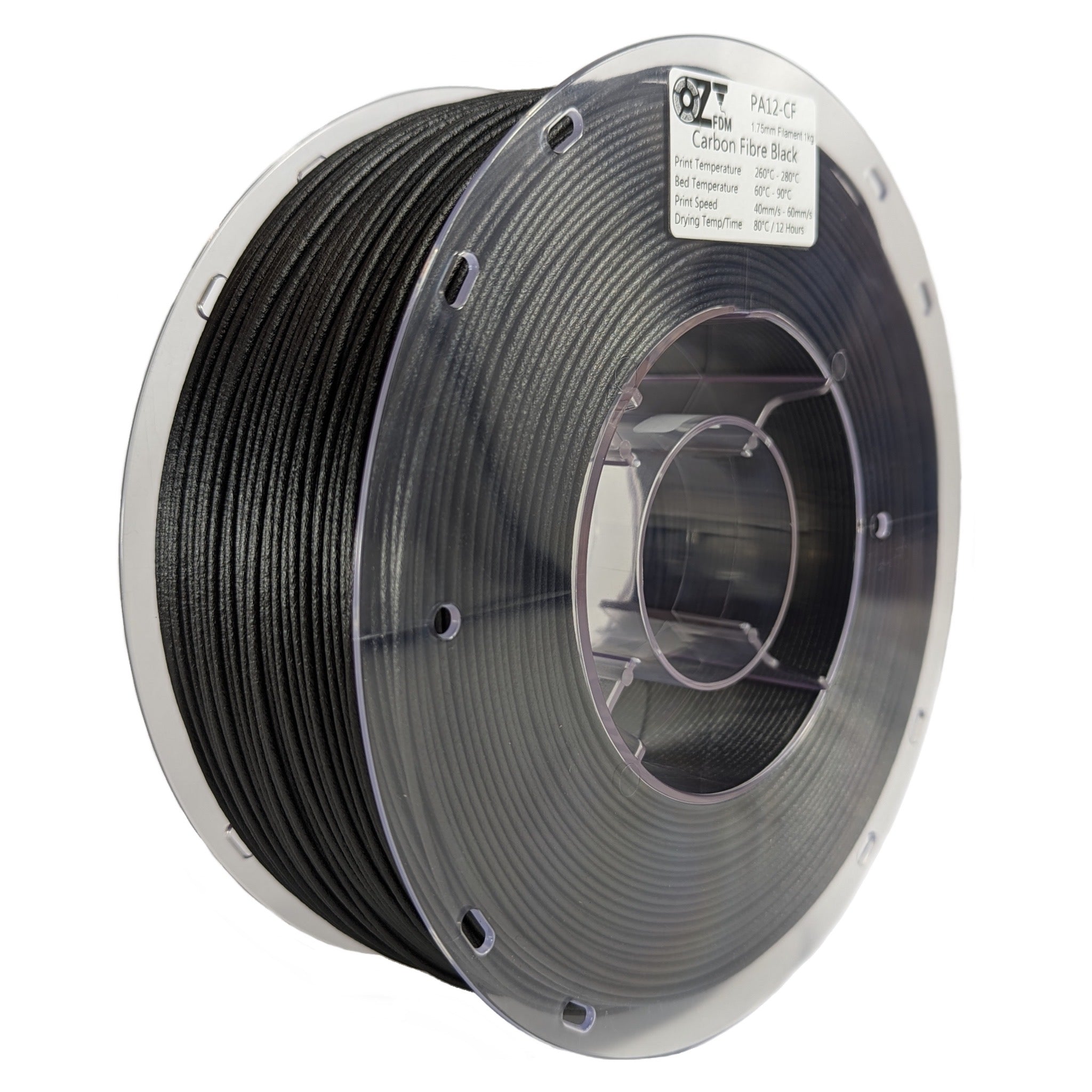

1.75 mm PA12-CF Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

OzFDM PA12-CF is a high-performance nylon material, consisting of 85% LUVOCOM 3F PAHT CF Nylon12 and 15% carbon fibre. Offering excellent strength, stiffness and heat resistance, it's ideal for demanding applications. Post-printing, annealing for 3 hours at 80-100°C is recommended for optimal results.

Product specifications:

| Filament weight | 1KG |

| Filament diameter | 1.75mm |

| Dimensional tolerance | ±0.05mm |

| Spool weight (empty) | 150g |

| Spool weight (new) | 1.15KG |

| Spool diameter outer | 200mm |

| Spool diameter inner (hub) | 52mm |

| Spool width | 65mm |

| Package weight | 1.3KG |

| Package dimensions | 210mm x 210mm x 75mm |

Print parameters:

| Nozzle temperature | 260°C - 280°C (270°C recommended) |

| Bed temperature | 60°C - 90°C (80°C recommended) |

| Printing speed | 40mm/s - 60mm/s (50mm/s recommended) |

| Support material | PVA |

Physical Properties:

| Density | ISO 1183 | 1.23~1.26 g/cm3 |

| MFR(250°C/2.16Kg) | ISO 1133 | 3~6 g/10min |

| Moisture Absorbtion(23°C/24h) | ISO 62 | <0.3 % |

Mechanical Properties:

| Tensile Strength | ISO 527 | 50~55 Mpa |

| Elongation at Break | ISO 527 | 3.5~4.5 % |

| Flexural Modulus | ISO 527 | 1300~1500 Mpa |

| Flexural Strength | ISO 178 | 90~96 Mpa |

| Impact Strength | ISO 180 | 3.5~5 KJ/m² |

Thermodynamic Properties:

| HDT @ 0.455 Mpa(66 psi) | ISO 75 | 90 °C |

| Continuous Use Temperature | IEC 60216 | 120 °C |

| Use Temperature(200 hours) | 160 °C |

Electrical Characteristics:

| Insulation Resistance | IEC 60167 | ≤10² Ω |

| Surface Resistance | IEC 60093 | ≤10² Ω |

Drying recommendation:

80°C for a minimum of 12 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.