1.75 mm ABS Filament - 1 KG

Tax included. Shipping calculated at checkout

ABS Filament Bulk Pricing

- Buy any 3+ rolls of ABS filament and save 5%

- Buy any 6+ rolls of ABS filament and save 10%

- Buy any 12+ rolls of ABS filament and save 15%

Choose options

OzFDM ABS Filament

OzFDM’s ABS (Acrylonitrile Butadiene Styrene) 1.75 mm filament is a tough, engineering grade material built for high strength, functional printing. Designed for makers who need reliability and performance, ABS is well known for its impressive impact resistance, heat tolerance, and long term durability, making it a staple for both industrial and hobbyist use. It offers a balanced combination of strength and stability that allows it to perform under demanding mechanical and environmental conditions without compromising print quality.

The material works well because of its special structure: butadiene gives it strength and flexibility, while acrylonitrile improves its resistance to chemicals and heat, helping printed parts stay strong under pressure. This mix of chemicals makes ABS strong and able to handle impacts and high temperatures without changing shape. The result is sturdy, dimensionally accurate prints with a clean matte finish and minimal brittleness, ensuring every part looks and performs consistently. From mechanical fixtures and enclosures to tools, prototypes, and even LEGO-style builds.

The Only Shade You Need

Print in Neutral - ABS Colour Range

Our ABS colour range features a clean, natural hue that adds subtle sophistication to any print. The neutral tone strikes the perfect balance, bright enough to stand out, yet soft and sleek enough to maintain a professional finish.

It’s a timeless shade that complements functional parts, prototypes, and display pieces alike, bringing clarity and simplicity to your creations.

Smoother Extrusion, Reduced Warping,

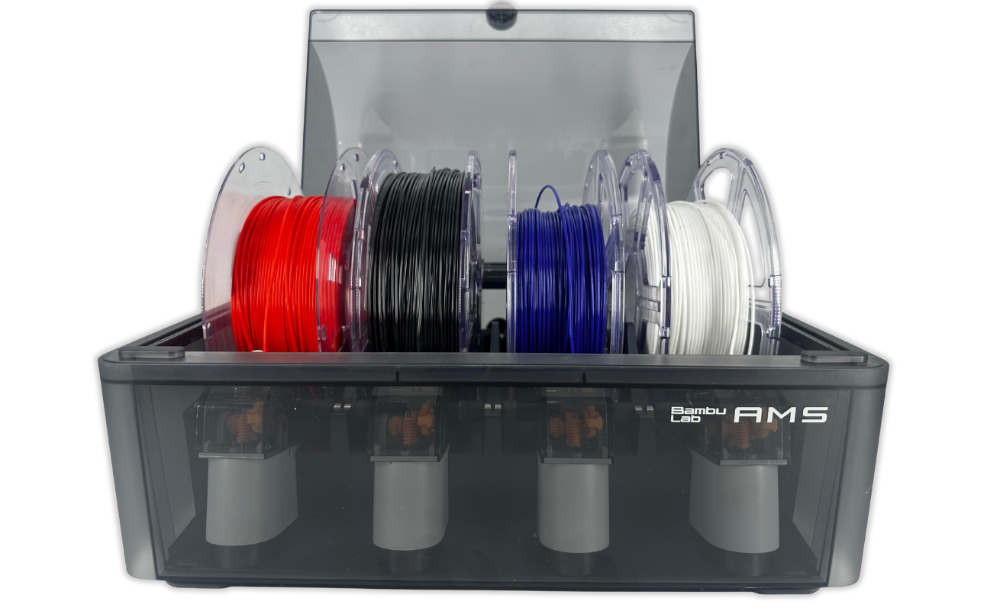

ABS Performance Meets AMS Precision

- When used with an AMS system, OzFDM ABS performs exceptionally well for multi-spool management and consistent material handling.

- The controlled environment of an AMS helps maintain stable temperatures and humidity levels, reducing the risk of warping and moisture absorption during longer print sessions.

- It also allows for seamless transitions between colours or materials while ensuring each spool remains sealed and protected when not in use.

- This setup enhances reliability, improves print consistency, and makes working with ABS far more convenient for both professional and high volume users.

Strength Meets Stability

High Strength & Impact Resistance

OzFDM ABS delivers the robust mechanical strength makers rely on for functional and structural parts.

Its reinforced polymer blend withstands heavy use, stress, and repeated impact without fracturing, making it ideal for mechanical prototypes, fixtures, and durable end use components.

Whether it’s load bearing designs or daily functional prints, ABS provides dependable toughness that lasts.

Heat and Chemical Stability

Engineered for environments where standard PLA falls short, ABS maintains its shape and performance under elevated temperatures.

The material resists softening and deformation, ensuring dimensional accuracy even in heat prone or high friction applications.

Its resistance to oils, greases, and common industrial chemicals makes it a trusted choice for real world utility and professional grade printing.

Smooth Finish & Post-Processing Flexibility

ABS produces a clean, matte surface straight off the printer and responds exceptionally well to finishing techniques.

It can be easily sanded, drilled, or vapour-smoothed for a polished appearance and increased strength.

This versatility allows makers to achieve production quality results, blending functionality with a professional finish that enhances both the look and performance of every print.

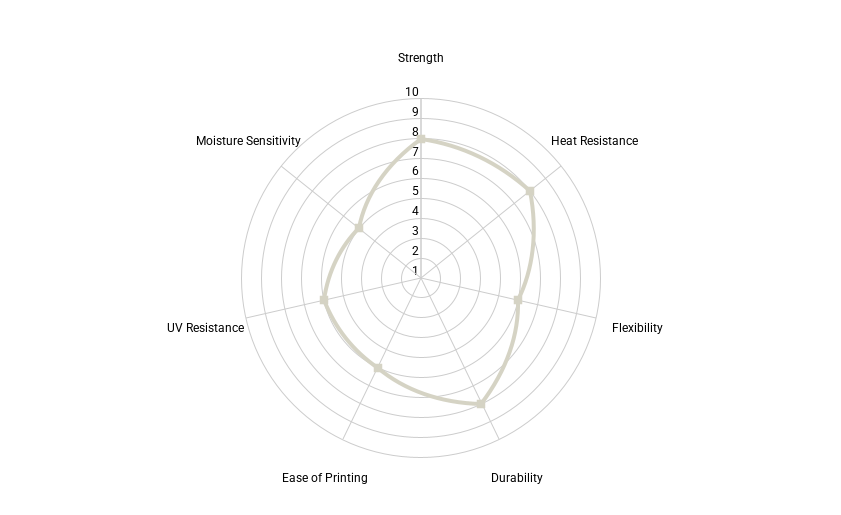

ABS's Personality on a Radar Chart

Understanding ABS at a Glance

- The results indicate that OzFDM ABS excels in strength, heat resistance, and long term durability, making it ideal for functional and mechanical applications.

- While it requires slightly more controlled printing conditions than PLA, it offers excellent structural stability once dialled in.

- Its dependable performance and solid balance of mechanical properties make it a go to filament for makers seeking professional, high strength prints.

ABS Technical Specifications

Each spool of OzFDM’s premium ABS filament is securely vacuum-sealed with a moisture-absorbing desiccant to maintain optimal print quality right up to that special moment you open the box.

Every package includes recommended printing and drying settings, ensuring you achieve smooth, consistent results right from your first layer.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.03mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

80°C for 5 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

ABS performs best with a heated bed and enclosed chamber, maintaining consistent temperature control to prevent warping or cracking. Optimised print settings help achieve strong layer adhesion and a smooth surface finish for dependable, high-quality results.

For best results, follow the recommended print parameters provided below to achieve reliable, high-quality prints every time.

Nozzle temperature

220°C - 240°C

Bed temperature

80°C - 110°C

Printing speed

40mm/s - 300mm/s

Support material

Known for its durability and impact resistance, ABS offers the strength required for functional components, tools, and enclosures. Its excellent rigidity and toughness allow prints to withstand daily wear and demanding mechanical use.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

45~40 Mpa

Elongation at Break

ISO 527

12~17 %

Flexural Modulus

ISO 527

1500~1650 Mpa

Flexural Strength

ISO 178

65~70 Mpa

Impact Strength

ISO 180

7~10.5 KJ/m²

This filament produces dense, precise prints with a naturally matte surface and minimal shrinkage when printed correctly. The material’s stability and balanced strength-to-weight ratio make it ideal for both professional and everyday applications.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.04~1.06 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

2~6 g/10min

Moisture Absorbtion (23°C/24h)

ISO 62

1 %

ABS maintains dimensional stability under elevated temperatures and resists deformation from heat exposure. Its high glass transition temperature allows for consistent performance in environments where thermal resistance is key.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

88 °C

Continuous Use Temperature

IEC 60216

-