1.75 mm PC-CF Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

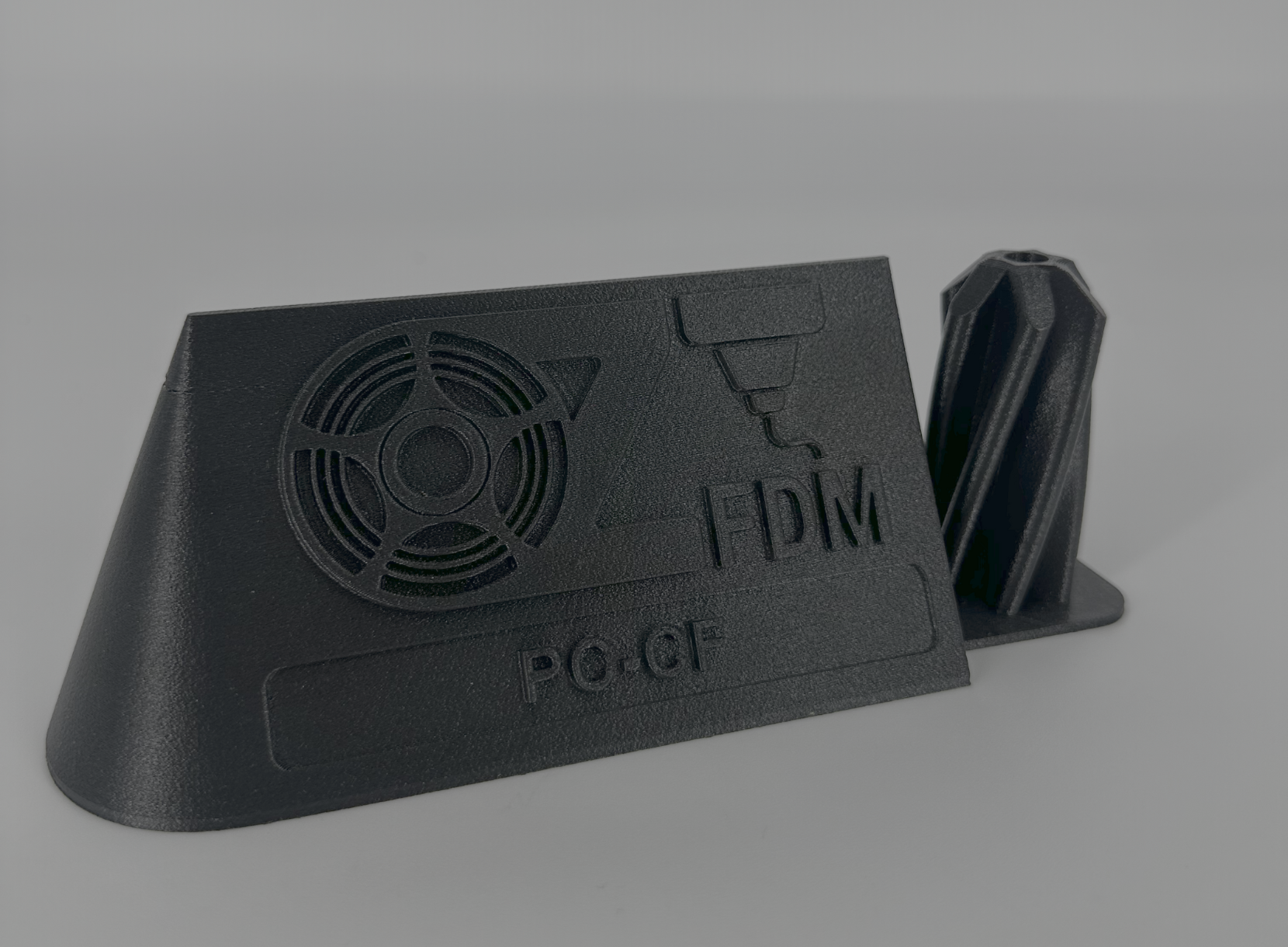

OzFDM PC-CF Filament

PC-CF (Polycarbonate Carbon Fibre) delivers exceptional strength, stiffness, and heat resistance through the powerful combination of polycarbonate and finely distributed carbon fibre. Built for professional applications, this filament performs where other high grade materials like PETG-CF or ASA-CF may begin to flex or soften. While PETG-CF focuses on easy, reliable printing and ASA-CF excels in outdoor and UV exposed applications, PC-CF stands out as the true engineering grade option built for precision components, mechanical assemblies, and parts that must endure stress without deformation.

By infusing the PC-CF base with microscopic strands of carbon fibre, the material gains significant rigidity and reduced thermal expansion, helping each layer lock firmly in place as it cools. The reinforcement acts much like rebar within concrete, enhancing structural integrity while lowering overall weight. The carbon fibres also contribute to a matte, textured surface that hides layer lines and improves interlayer bonding resulting in prints that feel as strong as they look while maintaining exceptional dimensional stability even under continuous stress or elevated temperatures, making it a trusted choice.

PC-CF delivers a refined, technical finish and dependable performance for functional prototypes or final assemblies, perfect for makers seeking versatility. From simple prints to real-life conditions, it excels in automotive and industrial uses, offering professional grade performance in precision and strength.

Built for performance, finished for perfection, the ultimate blend of form and function.

PC-CF Black Carbon Fibre

Black Carbon Fibre presents a deep matte black finish with a subtle metallic texture that reflects its carbon reinforcement. The fine fibre pattern gives the surface a distinctive, high quality engineering look that hides layer lines and enhances detail definition. Sleek, consistent, and purposefully understated, this colour embodies the strength PC-CF is known for. ideal for parts where performance and professional aesthetics go hand in hand.

Keep It Dry, Keep It Controlled

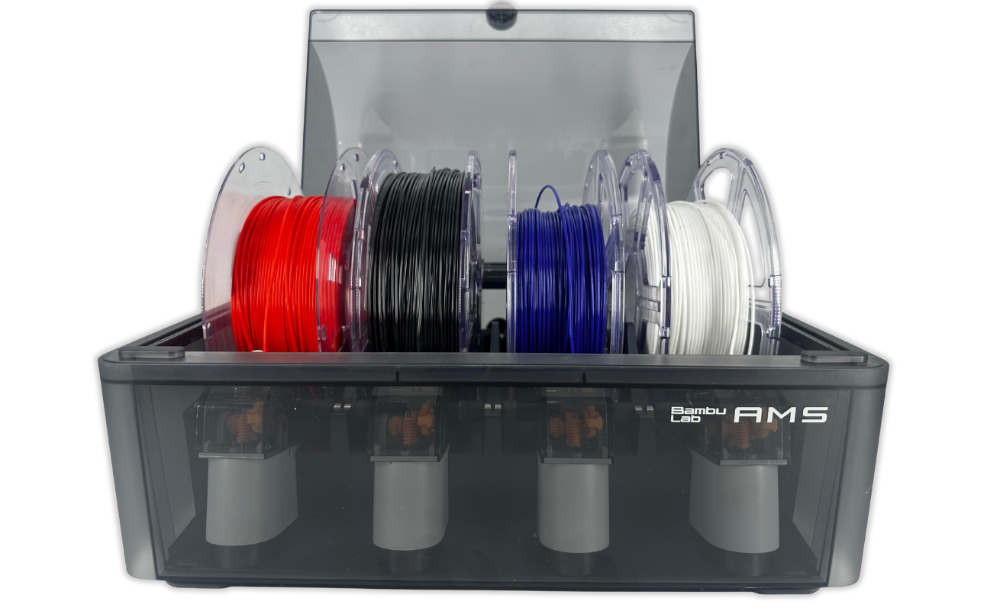

AMS-Compatible, Handle with Care

PC-CF can be used with AMS systems when stored and managed correctly, due to its polycarbonate base and carbon fibre reinforcement, the material is highly moisture sensitive and performs best when kept completely dry during printing. Even small amounts of absorbed moisture can cause popping, stringing, and a rough surface finish, affecting both layer adhesion and part strength of your printed model.

For smooth feeding and consistent results, store the spool in a sealed dry box or actively dried enclosure connected to the AMS. PC-CF’s higher extrusion and bed temperatures demand an enclosed printer setup, having this environment helps the part cool gradually, preventing stress along sharp edges or large flat surfaces. However, when managed properly, the AMS will handle it reliably. Delivering strong, precise prints without feed interruptions or surface inconsistencies.

Advanced Performance for Demanding Prints

Built for Demanding Performance

PC-CF stands out for its ability to perform in conditions that would challenge most filaments. With its reinforced polycarbonate base, it resists deformation under load and retains exceptional strength even in elevated temperatures.

This makes it ideal for components that experience real world stress, such as brackets, enclosures, mechanical joints, and functional assemblies.

Whether used for industrial prototypes or high performance final application parts, PC-CF delivers the structural reliability needed when precision and strength cannot be compromised.

Strength in Every Layer

The addition of finely milled carbon fibres transforms polycarbonate into a composite built for consistency and control.

Each strand helps stabilise the material as it cools, reducing warping while increasing rigidity and dimensional accuracy. The result is a filament that maintains its shape across complex geometries and large prints.

Combined with the natural impact resistance of polycarbonate, PC-CF produces parts that are both lightweight and exceptionally strong, with a professional matte carbon finish that conceals layer lines and surface imperfections.

Designed for Precision and Longevity

Beyond its physical performance, PC-CF is valued for its durability over time. It offers excellent chemical resistance, maintains integrity under repeated mechanical stress, and provides reliable performance in environments where heat, vibration, or movement are constant factors.

This makes it an excellent choice for applications such as drone frames, custom tooling, or high-strength replacement parts.

When properly dried and printed within the recommended conditions, PC-CF delivers a level of quality and repeatability suited to advanced engineering and production-grade results.

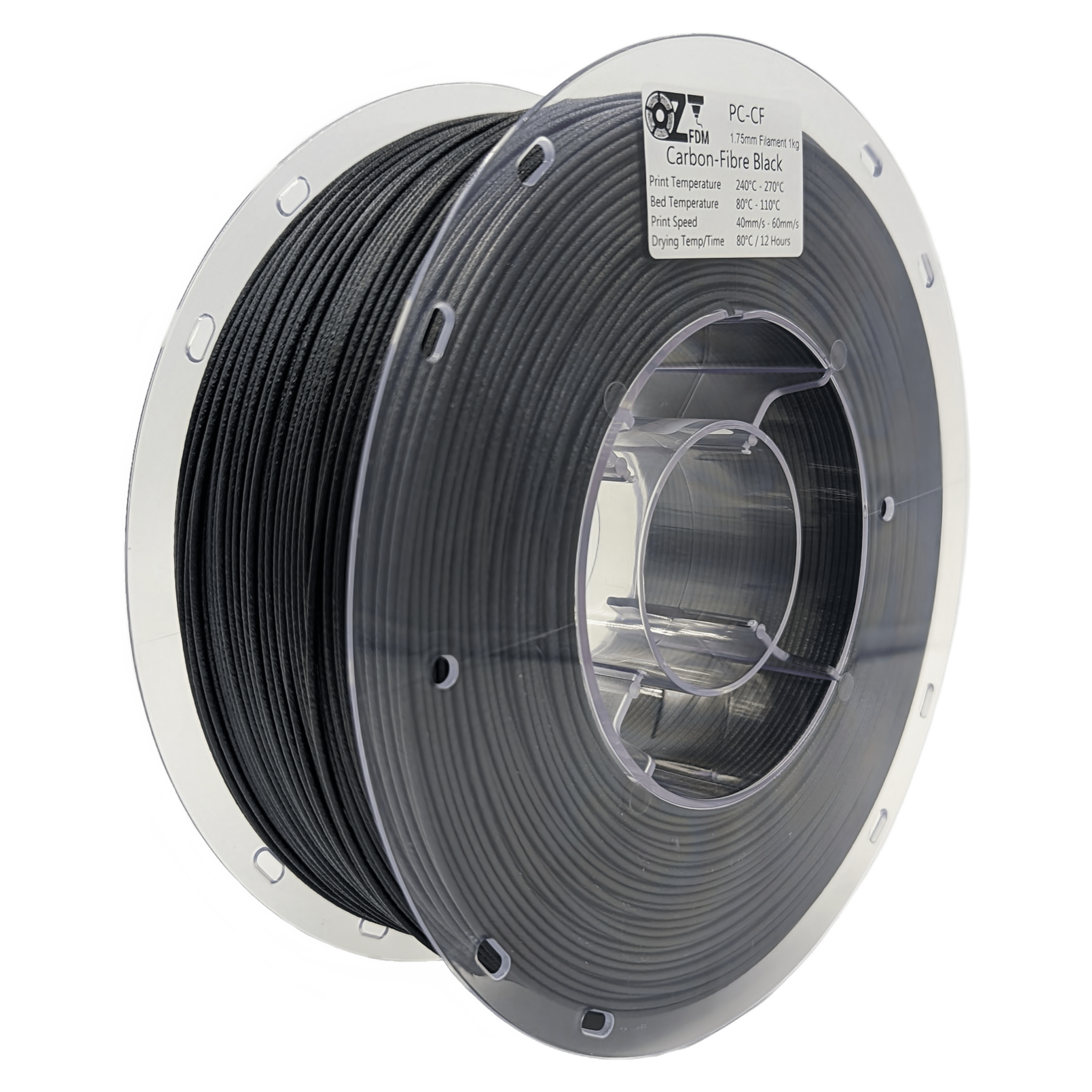

PC-CF Technical Specifications

Each spool of OzFDM’s premium PC-CF filament is securely vacuum-sealed with a moisture-absorbing desiccant to maintain optimal print quality right up to that special moment you open the box.

Every package includes recommended printing and drying settings, ensuring you achieve smooth, consistent results right from your first layer.

For additional details on packaging, storage, and shipping, see the information provided below.

Filament weight

1KG

Filament diameter

1.75mm

Dimensional tolerance

±0.05mm

Spool weight (empty)

150g

Spool weight (new)

1.15KG

Spool diameter outer

200mm

Spool diameter inner (hub)

52mm

Spool width

65mm

Package weight

1.3KG

Package dimensions

210mm x 210mm x 75mm

Drying recommendation:

80°C for minimum of 12 hours using a filament dryer / food dehydrator.

Storage recommendation:

Airtight bag or container with desiccant in a cool, dark and dry area to prevent moisture absorption. For optimal long term storage we recommend drying the filament prior to sealing the filament spool in a vacuum bag with desiccant.

Biodegradable under commercial composting conditions. Please do not throw into your compost bin at home.

PC-CF performs best under precise, high temperature printing conditions that support strong layer bonding and controlled cooling. Maintaining a stable environment ensures the filament’s full strength, dimensional accuracy, and premium surface finish are achieved throughout the print.

For best results, follow the recommended print parameters provided below to achieve reliable, high-quality prints every time.

Nozzle temperature

260°C - 300°C

Bed temperature

100°C - 120°C (110°C recommended)

Printing speed

40mm/s - 60mm/s

Support material

PC-CF (Self Supported)

This material is built for serious strength, combining rigidity and impact resistance with a lightweight structure. The carbon fibre reinforcement enhances stiffness and stability, making PC-CF ideal for demanding functional parts and precision engineered models.

For a deeper look at strength, durability, and tested material performance, refer to the mechanical property data outlined below.

Tensile Strength

ISO 527

38 Mpa

Elongation at Break

ISO 527

10 %

Flexural Modulus

ISO 527

-

Flexural Strength

ISO 178

85 Mpa

Impact Strength

ISO 180

5~8 KJ/m²

PC-CF performs best under precise, high temperature printing conditions that support strong layer bonding and controlled cooling. Maintaining a stable environment ensures the filament’s full strength, dimensional accuracy, and premium surface finish are achieved throughout the print.

For a closer look at density, flow rate, and moisture resistance, see the physical property data outlined below.

Density

ISO 1183

1.20~1.25 g/cm3

MFR(250°C/2.16Kg)

ISO 1133

5~7 g/10min

Moisture Absorption (23°C/24h)

ISO 62

<0.5 %

Engineered to withstand high temperatures and extended operational stress, PC-CF maintains its form and strength even in demanding environments. Its thermal stability and low deformation under heat make it an exceptional choice for applications that require lasting performance under pressure.

For detailed insights on heat deflection and continuous use ratings, refer to the thermal property data provided below.

HDT @ 0.455 Mpa (66 psi)

ISO 75

125 °C

Continuous Use Temperature

IEC 60216

120°C- 130°C