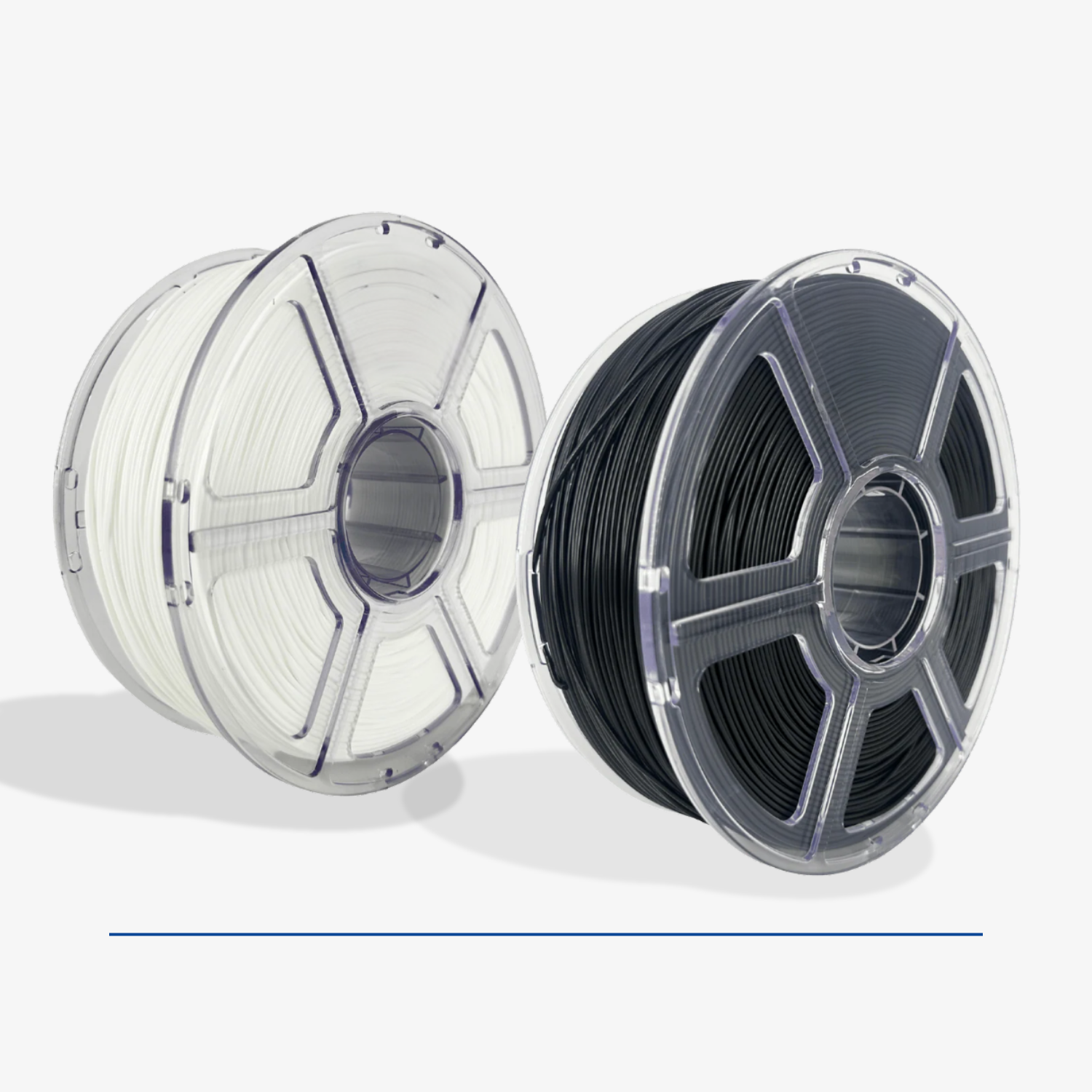

1.75 mm PolyPropylene (PP) Filament - 1 KG

Tax included. Shipping calculated at checkout

Store-wide Bulk Filament Pricing

- Buy any 3+ rolls of filament and save 5%

- Buy any 6+ rolls of filament and save 10%

- Buy any 12+ rolls of filament and save 15%

Choose options

PolyPropylene (PP) Filament

Polypropylene (PP) is a lightweight, tough, and chemically resistant engineering filament that is ideal for functional parts that need to bend, flex, and keep performing. With excellent fatigue resistance and low density, PP is perfect for living hinges, snap-fits, and containers that must handle everyday knocks without cracking. It resists many household chemicals and moisture, making it a great choice for jigs, fixtures, storage solutions, and working prototypes.

While PP can need a bit more printing precision than PLA , the payoff is durable, practical parts with an appealing, semi-translucent finish.

Optimise your setup with the right build surface and adhesion strategy, and you’ll unlock clean, consistent results that make PP a go-to material for everyday use.

Essential Colours for Everyday Printing

OzFDM’s PP filament is available in practical, maker-focused tones designed for clarity, contrast, and durability.

OzFDM’s PP filament range features a growing palette of colours designed for functionality, visibility, and consistency. Each shade is carefully formulated for clean finishes, dependable performance, and professional-quality results across every print. Whether you’re prototyping, testing, or producing final parts, expect reliability and precision in every roll.

Disclaimer on Colour Accuracy: The filament colours displayed have been specified using online hex code sources and may vary slightly from the actual physical product due to differences in screen calibration, lighting, and digital representation. Please note that this colour range is subject to refinement once our Nix Mini 3 Colour Sensor arrives, allowing us to assess and scan each filament shade in person for greater accuracy.

For makers who need strength that flexes with their design.

Flexibility Meets Durability

PP’s natural flexibility allows parts to bend, twist, and return to shape without cracking. This makes it perfect for living hinges, snap-fits, clips, and containers that need to handle repeated use. You get the strength and toughness of an engineering polymer while maintaining lightweight performance — ideal for functional prints, everyday prototypes, and practical designs that demand resilience.

Built for Strength and Longevity

Flexible Strength for Real-World Parts

PP shines when your design needs to bend without breaking. It offers outstanding fatigue resistance for living hinges, snap-fits, and parts that experience repeated movement. Clips, lids, straps, and containers benefit from PP’s combination of impact resistance and low density, delivering sturdy yet lightweight components. The material’s semi-translucent appearance also makes it great for enclosures that need light transmission or visual inspection. If you have been pushing PLA beyond its comfort zone for functional prints, PP provides the next step up—more durability, more resilience, and a finish that looks and performs like a production material.

Print Tips for Reliable Adhesion

PP does not bond well to glass or PEI, so the right surface is essential. For best results, print on a PP-friendly build surface (polypropylene sheet), packing tape with a PP layer, or a dedicated polypropylene build plate. Use a brim to stabilise edges, and consider draft shields or an enclosure to minimise warping on larger parts. Moderate bed temperatures help with first-layer grip; tune your first-layer height carefully for a slightly squished line that promotes contact without elephant’s foot. Keep cooling conservative to support layer bonding, and avoid strong airflow that can shrink edges.

Design Smarter: Hinges, Snaps, and Fit

Lean into PP’s strengths by designing living hinges with gradual transitions and adequate thickness (typically 0.3–0.6 mm for the thinnest hinge section, then test and iterate). For snap-fits, allow sensible clearance so parts flex rather than stress the latch. Chamfers and fillets reduce stress concentrations and improve durability. Where threads are required, consider thread-forming screws or use heat-set inserts in reinforced bosses made from a compatible material if the application demands repeated assembly. Finally, prototype small, tweak dimensions, and scale up—PP rewards thoughtful design with long-lasting, dependable parts.